MCC is one of the leading hand tool manufacturers in Japan, as well as one of the oldest companies in the industry. Since Mr. Anzai, the founder of MCC had started his casting factory in 1916, his never-give-up effort and wise investment for improving the product and quality had brought his company very much success towards a solid enterprises which owns not only manufacturing facilities, but also has its own in-house R&D department which constantly releases many innovative products year after year. To add to the list of accolades, MCC has three sales companies including an international sales office which provides an outlet to the international market.

Unique tools and well-designed feature for the users

As the first manufacturer in Japan to mass-produce Bolt Cutters and Pipe Wrenches, MCC has been introducing numerous innovative products to the market. Through the years of activity in establishing the know-how and basis in R&D towards innovative and creative technologies, MCC currently is recognized as one of the top innovative manufacturers in the hand tools industry in Japan. PVC Pipe Cutter, Corner Wrench, Threaded Rod Cutter, Multi-Layer Wire Stripper and Foot Vises are the products that were developed from the end user’s needs and originally designed by the team at MCC R&D department.

First process after raw materials

MCC is known for its strict standards in its raw materials in the production of its hand tools. Through our research and development we can conclusively state that high quality raw materials is just as important as machining tolerances in the production and finish of the superiority of our tools. That’s the reason why MCC sources our raw materials only from a few of the high-end Japanese steel manufacturers. After receive-in inspection of raw materials, the first process will take place in one of the MCC’s plant such as casting or forging plant in Mie prefecture, Japan.

Total Management

Strict Quality Control throughout the entire manufacturing process. Establishing manufacturing know-how and technologies for more than 90 years, MCC now owns and operates its own in-house forging and casting factory, heat treatment and surface treatment facilities along with hundreds of machining equipment. This allows us to monitor and manage the product quality at every process of manufacturing. While we appreciate our loyal customers and end users, we are responsible for quality control and safety of our products.

Assembling and Final Quality Inspection

The lowest rate of defective or failure of a product is one of the key for staying on top of the market. Since the first MCC product was packaged in the box, our assembly line ensures that every single unit of a product is well-built and ready for tough work by manually operated inspection station for many years. Because the tool is a sort of an extension of the human body, we believe that the final test by humans is very important as the last health checkup of a product.

Sufficient domestic stock for quick delivery

In order to meet our end-user’s daily needs, we stock large volumes of inventory at our main warehouse in Japan by supplying the fulfillment request from the local stock distributors in each country. According to their requirements, air and sea shipments are leaving to our distributors and end user’s on a daily basis.

MCC Worldwide

We export products to more than 50 countries all over the world for the demands at job sites. MCC International Inc. in Osaka Japan and MCC USA Inc. in California maximize their marketing and product exposure in order to support MCC dealers and distributors. Our stocking distributors know that their professional users in their market can rely on the excellent quality of MCC products. MCC is now recognized as a worldwide brand for its high quality and reliability. That’s why people call MCC, “Tool for Professional.”

MCC, short for Matsuzaka Cast Steel & Co., is a renowned company with a rich history in the manufacturing and production industry. Established in 1916 in Japan, MCC has evolved and adapted over the years to become a leading provider of cutting tools and machining jigs. The company’s origins trace back to the vision of its founder, Tomokich Anzai, who assembled a skilled engineering team by recruiting top casting engineers from various cities in Japan. With a strong business sense honed through years of experience as a successful salesman, Anzai steered MCC towards great success by aligning its operations with the growing Japanese economy.

Initially specializing in manufacturing lathe machines, MCC expanded its product line to include a variety of hand tools. In 1928, the company achieved a significant milestone by becoming the first in Japan to manufacture pipe wrenches and bolt cutters. This marked the beginning of MCC’s core business in hand tools, which has remained a prominent aspect of their operations. Over time, MCC further diversified its offerings to include cutting pliers and other common tools, solidifying its reputation as a leading provider in the industry.

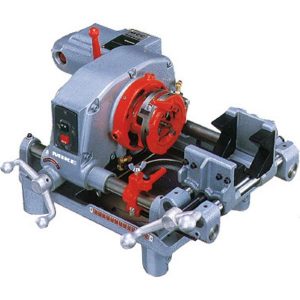

The company’s commitment to innovation and quality has been evident throughout its history. MCC obtained patents for various inventions, including a pipe threading machine, PVC pipe cutter, foot vises, multi-layer wire stripper, and threaded rod cutter. These inventions not only showcased MCC’s ingenuity but also contributed to the efficiency and productivity of industries reliant on their tools.

In addition to their domestic growth, MCC expanded its presence globally. With the establishment of MCC USA Inc. in Los Angeles, California in 1979, the company entered the international market, catering to customers worldwide. They also established MCC International Inc., further strengthening their position as a global player in the industry.

Today, MCC is recognized not only in the construction and plumbing sectors but also in the wider manufacturing and production industry. Known for their high-quality, precision products, MCC has earned a stellar reputation as an industry leader in the machining jig field. Their commitment to customer service and professional design consultation has solidified their position as a trusted partner for businesses worldwide.

With a century-long history of innovation, adaptability, and dedication to excellence, MCC continues to thrive as a prominent player in the manufacturing and production industry, setting the benchmark for cutting tools and machining jigs.

MCC

Showing 1–45 of 89 results