In the context of tools like V-Blocks and Prism Pairs, “Grade” refers to the level of precision and the accepted tolerance during the manufacturing process. This is a crucial factor, especially in engineering and industrial applications where high accuracy is essential.

- Grade 0: This is the highest precision level, with a very low parallelism tolerance, typically ±0.008 mm. This means the surfaces of the blocks in the V-Block or Prism Pair are ground to such a fine degree that the maximum deviation between parallel surfaces is 0.008 mm. This grade is suitable for applications requiring extremely high accuracy.

- Grade 1: This precision level has a slightly higher tolerance, at ±0.016 mm. It still provides good accuracy and is suitable for most industrial and engineering applications.

- Grade 3: This is the lowest precision level among the three, with a tolerance of ±0.064 mm. While it does not offer the high accuracy of the previous grades, it is still adequate for many applications where ultra-high precision is not required.

These precision levels are typically applied to both versions of V-Blocks and Prism Pairs, including the ground (finely finished) version and the milled (machined) version. The choice of precision level depends on the specific requirements of the application, as well as budgetary and other technical considerations.

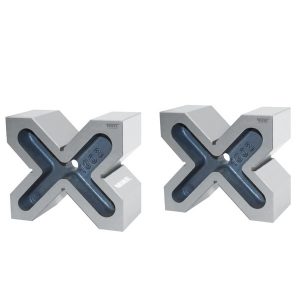

V-Block

Showing all 6 results