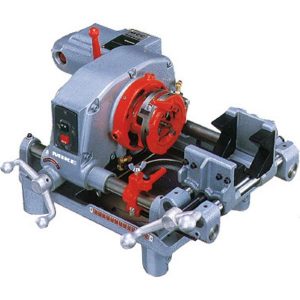

A pipe threading machine is a specialized tool used in industrial settings to create threads on the end of pipes. These threads enable pipes to be securely joined together using fittings, connectors, or valves, forming a leak-proof seal for fluid or gas transmission systems. Pipe threading machines typically consist of a motor-driven spindle, a die head, and various cutting and guiding tools.

How a pipe threading machine generally works:

- Preparation: The pipe to be threaded is placed securely in the machine’s chuck or clamping mechanism. The pipe is positioned horizontally or vertically, depending on the machine’s design and the operator’s preference.

- Selection of Die: The appropriate die size and threading specifications are selected based on the diameter and threading requirements of the pipe. Dies come in various sizes and thread types to accommodate different pipe dimensions and standards, such as NPT (National Pipe Thread) or BSPT (British Standard Pipe Thread).

- Thread Cutting: The motor-driven spindle rotates the pipe at a controlled speed while the die head, equipped with the selected die, moves along the length of the pipe. As the die head advances, it cuts precise threads onto the pipe’s outer surface. The cutting process may involve multiple passes to achieve the desired thread depth and quality.

- Oiling: During the threading operation, cutting oil or lubricant is often applied to the pipe and dies to reduce friction, dissipate heat, and improve thread quality. Some advanced pipe threading machines feature automatic oiling systems for consistent lubrication throughout the threading process.

- Completion: Once the threading process is complete, the pipe is removed from the machine. The threaded end of the pipe is inspected to ensure it meets the required specifications and standards for fit and finish.

Pipe threading machines are commonly used in industries such as plumbing, construction, manufacturing, and oil and gas. They offer precise control over thread dimensions, consistent quality, and increased efficiency compared to manual threading methods. Additionally, modern pipe threading machines may include advanced features such as automatic thread depth adjustment, digital controls, and safety mechanisms to enhance productivity and operator convenience.

MCC, known for its precision engineering and commitment to quality, presents a range of Pipe and Bolt Threading Machines designed to meet the diverse needs of industries worldwide. Made in Germany, these machines combine robust construction with advanced features for efficient and accurate threading operations.

The MCC series encompasses a variety of models tailored to different pipe and bolt threading requirements, ensuring versatility and reliability across various applications. Let’s explore some key features and specifications of these exceptional machines:

MCC250 and MCC400:

- The MCC250 and MCC400 models are ideal for threading pipes ranging from 1/4″ to 1.1/2″ BSPT or NPT, offering unparalleled precision and efficiency.

- Equipped with a single-phase motor adaptable to local voltage, these machines ensure consistent performance under diverse operating conditions.

- The automatic oiling system, coupled with adjustable oil volume control, ensures smooth threading operations and prolongs tool life.

- Featuring a front chuck with replaceable rocker-type jaws, these machines provide secure gripping and easy adjustment for different pipe sizes.

MCC500 and MCC800:

- Designed for heavier-duty applications, the MCC500 and MCC800 models handle pipe sizes ranging from 1/4″ to 3″ BSPT or NPT, catering to a broader range of industrial needs.

- With a powerful single-phase motor adaptable to local voltage, these machines deliver high torque and reliable performance, even in demanding environments.

- The inclusion of a self-opening pipe die head (MCC500) and manual pipe die head (MCC800) offers flexibility to accommodate various threading requirements.

- Both models feature an automatic switch-off carbon brush system, safeguarding the motor against overheating and ensuring long-term durability.

Standard Accessories:

- Each MCC machine comes with a comprehensive set of standard accessories, including pipe die heads, pipe dies, cutting oil, spindle bearing oil, hex keys, screwdrivers, carbon brushes, machine covers, and toolboxes, facilitating immediate setup and operation.

- Optional accessories such as additional die heads, pipe supports, bolt die heads, and conduit pipe dies are available to further enhance the versatility and functionality of the machines.

Built to the highest German engineering standards, MCC’s Pipe and Bolt Threading Machines offer unparalleled performance, durability, and versatility for threading operations in diverse industrial settings. Whether it’s threading pipes or bolts, MCC machines deliver precision, efficiency, and reliability you can trust. Experience the difference with MCC – Precision Engineering at its finest.

What is a bolt threading machine?

A bolt threading machine, also known as a bolt threader or bolt threading equipment, is a specialized tool used to create threads on the end of bolts, studs, or rods. These threaded fasteners are essential components in various industries, including construction, manufacturing, automotive, and aerospace, where they are used for assembly, fastening, and structural applications.

Here’s an overview of how a bolt threading machine typically operates:

- Preparation: The bolt or rod to be threaded is securely clamped or held in place within the machine’s chuck or vice. Depending on the machine design, the bolt may be positioned horizontally or vertically for threading.

- Selection of Die: Similar to pipe threading machines, bolt threading machines utilize dies to cut threads onto the bolt’s surface. The appropriate die size and threading specifications are selected based on the diameter, pitch, and thread type required for the bolt. Dies come in various sizes and thread standards to accommodate different bolt dimensions and threading requirements.

- Thread Cutting: The machine’s motor-driven spindle rotates the bolt at a controlled speed while the die head, equipped with the selected die, moves along the length of the bolt. As the die head advances, it cuts precise threads onto the bolt’s surface. The cutting process may involve multiple passes to achieve the desired thread depth and quality.

- Lubrication: Cutting oil or lubricant is often applied to the bolt and dies during the threading process to reduce friction, dissipate heat, and improve thread quality. Lubrication helps prolong the life of the cutting tools and ensures smooth and accurate threading.

- Completion: Once the threading operation is complete, the bolt is removed from the machine. The threaded end of the bolt is inspected to ensure it meets the required specifications and standards for fit, thread pitch, and thread quality.

Bolt threading machines offer several advantages over manual threading methods, including increased speed, precision, and consistency in thread production. They are essential tools for high-volume production environments where threaded fasteners are manufactured in large quantities. Additionally, bolt threading machines may feature various options and accessories to accommodate different bolt sizes, thread types, and production requirements, providing versatility and efficiency in bolt threading operations.

What is the difference between bolt threading and pipe threading?

Bolt threading and pipe threading are two distinct processes used to create threads on different types of materials—bolts and pipes—each serving unique purposes in various industries. Here are the key differences between bolt threading and pipe threading:

- Material Type and Purpose:

- Bolt threading: Bolt threading involves creating threads on bolts, studs, or rods made of metal or other materials. Threaded bolts are primarily used for fastening and securing components together in assemblies, structures, and machinery.

- Pipe threading: Pipe threading is the process of creating threads on the ends of pipes. Threaded pipes are used for joining sections of pipes together, connecting pipe fittings, and assembling pipelines for conveying fluids or gases in plumbing, HVAC (heating, ventilation, and air conditioning), and industrial applications.

- Thread type and Standards:

- Bolt threading: Bolt threads typically follow specific standards, such as ISO metric threads or British Standard Whitworth (BSW) threads. These threads are standardized for compatibility with nuts, washers, and other fastening components.

- Pipe threading: Pipe threads can vary depending on the application and regional standards. Common pipe thread standards include National Pipe Thread (NPT), British Standard Pipe (BSP), and various international standards. Pipe threads are designed to create a tight seal when assembled with compatible fittings to prevent leaks in fluid or gas transmission systems.

- Equipment and Machinery:

- Bolt threading: Bolt threading machines, also known as bolt threaders, are used to cut threads on bolts, studs, or rods. These machines typically feature chucks or vices to securely hold the bolt during threading and are equipped with dies specifically designed for cutting bolt threads.

- Pipe threading: Pipe threading machines are specialized equipment designed for threading pipes. These machines may include features such as automatic oiling systems, die heads, and cutting tools tailored for threading pipe ends. Pipe threading machines are commonly used in plumbing, construction, and industrial settings.

- Application and Industry Usage:

- Bolt threading: Bolt threads are widely used in construction, manufacturing, automotive, aerospace, and other industries where fasteners are required to assemble components securely.

- Pipe threading: Pipe threads are essential for assembling pipelines, plumbing systems, and fluid or gas transmission networks in residential, commercial, and industrial buildings, as well as in oil and gas exploration and production facilities.

While bolt threading and pipe threading both involve creating threads on cylindrical materials, they serve distinct purposes and require specialized equipment tailored to their respective applications and industry requirements.

REMS Pipe threading machine

REMS offers a comprehensive range of pipe threading machines designed to meet various needs in the industry. From compact electric models to cordless options, REMS provides versatile solutions for threading pipes and bolts efficiently and effectively.

Starting with the REMS Amigo series, these electric die stocks with quick-change die heads are powerful and user-friendly. Available in different sizes, they can thread pipes ranging from ⅛ inch to 2 inches, catering to various applications. With features like maintenance-free gears, powerful motors, and safety switches, the Amigo series ensures smooth and safe operation.

For those seeking more mobility, the REMS Amigo 22 V offers cordless convenience. With a Li-Ion battery pack and rapid charger, it provides the freedom to work anywhere without the constraints of cords. Despite its compact size, the Amigo 22 V doesn’t compromise on power, making it ideal for on-the-go threading tasks.

Both the Amigo and Amigo 22 V series come with support brackets for added stability during operation. Additionally, the quick-change die heads enable easy and efficient threading, while the sturdy steel cases ensure convenient storage and transportation.

Furthermore, REMS offers a range of accessories such as the Nippelfix and Nippelspanner for efficient nipple-threading, providing users with versatile solutions to meet their specific threading needs.

REMS threading machines offer a blend of power, versatility, and convenience, making them essential tools for professionals in plumbing, construction, and maintenance industries. Whether it’s for large-scale projects or quick repairs on-site, REMS provides reliable solutions for all threading requirements.

REMS threading machine lineup, featuring prominent models like the REMS Magnum and REMS Unimat 75, embodies a sophisticated blend of advanced technology and robust design, crafted to meet diverse needs in the industrial, metalworking, and installation sectors. These threading machines offer precise and efficient solutions for cutting bolt and pipe threads, accommodating a wide range of sizes from the smallest to the largest, with threading capabilities from ¼ inch up to 4 inches depending on the model.

The REMS Magnum 4 inch, a high-performance, durable, and compact device, is designed for continuous operation with a maintenance-free drive system running in a sealed oil bath. This model stands out not only for its precision threading ability but also for its automatic lubrication and cooling system, extending the machine’s lifespan and ensuring top-quality thread output.

The REMS Unimat 75, a powerful semi-automatic machine, comes equipped with a strong 3-phase induction motor, offering high-efficiency and precise threading for bolts and pipes. It also features either automatic or hydraulic/pneumatic clamping, optimizing flexibility and efficiency in production processes.

Both REMS threading machine lines are engineered to meet the highest standards of safety, durability, and ease of use, with features like safety foot switches with emergency-stop functions, self-centering universal chucks, and versatile automatic die heads. These attributes not only boost work performance but also relieve the workload on expensive lathes and specialists.

With their capability to deliver high-quality, reliable threading solutions, REMS threading machines have become the go-to choice for many businesses in the industrial, metalworking, and installation fields worldwide.

Threading machine

Showing all 37 results