A spanner ratchet, also known as a ratcheting spanner or a combination ratchet spanner, is a specialized type of spanner or wrench that incorporates a ratcheting mechanism. It combines the features of a traditional open-ended spanner with the convenience of a ratchet.

The ratcheting mechanism allows for continuous rotation in one direction while preventing backward movement. This means that instead of having to reposition the spanner for each turn, the user can keep the spanner in place and simply move their hand back and forth to tighten or loosen a fastener. This makes the ratcheting spanner particularly useful in tight spaces where a full swing of the spanner is not possible.

The design of a spanner ratchet typically features a fixed open end on one side and a ratcheting box end on the other. The box end usually has a gear-like structure inside with small teeth or pawls that engage with the corresponding teeth on the fastener when the spanner is turned in one direction. This allows the user to apply torque to the fastener with minimal effort and without the need to remove and reposition the spanner for each turn.

Spanner ratchets are available in various sizes and configurations to accommodate different types of fasteners, such as nuts and bolts. They are commonly used in automotive repair, mechanical engineering, and other applications where the rapid tightening or loosening of fasteners is required.

It’s important to note that while spanner ratchets offer convenience and speed, they may not provide the same level of torque or strength as traditional fixed spanners. Therefore, it’s essential to use the appropriate size and ensure that the ratcheting mechanism is engaged securely to avoid slippage and potential damage to the fastener or the tool itself.

There are several different kinds of spanner ratchets available, each designed for specific applications and fastener types. Here are some common types of spanner ratchets:

- Combination Ratchet Spanner: This is the most basic type of spanner ratchet, featuring a fixed open end on one side and a ratcheting box end on the other. It is suitable for general-purpose use and is available in various sizes to fit different fasteners.

- Double-Ended Ratchet Spanner: This type of spanner ratchet has a ratcheting box end on both sides, allowing for increased versatility. It eliminates the need to constantly switch between different spanners, making it particularly useful in tight spaces or when working with multiple fasteners of the same size.

- Flex-Head Ratchet Spanner: A flex-head ratchet spanner features a flexible joint between the handle and the box end. This allows for greater maneuverability and access to fasteners in tight or hard-to-reach areas. The flex-head feature can be locked in a fixed position when needed.

- Stubby Ratchet Spanner: Stubby ratchet spanners are shorter in length compared to standard spanner ratchets. They are designed for use in confined spaces where a longer spanner may not fit. Despite their compact size, they still provide the convenience of a ratchet mechanism.

- Reversible Ratchet Spanner: Reversible spanner ratchets have a switch mechanism that allows the ratcheting direction to be changed easily. This feature is useful when you need to quickly switch between tightening and loosening fasteners without having to remove the spanner.

- Adjustable Ratchet Spanner: An adjustable ratchet spanner, also known as an adjustable wrench or an adjustable spanner, combines the ratchet mechanism with an adjustable jaw. This allows it to accommodate a range of different fastener sizes, providing added versatility.

These are just a few examples of the various kinds of spanner ratchets available. Each type has its own advantages and is designed to meet different needs and requirements. It’s important to choose the appropriate spanner ratchet for the specific task at hand to ensure safe and efficient work.

Ring ratchet spanners reversible

Ring ratchet spanners, also known as combination ratchet spanners, are versatile hand tools used for tightening or loosening fasteners, such as nuts and bolts. They are designed to provide both a box-end wrench and a ratcheting mechanism in a single tool.

The spanner features a ring-shaped or open-end wrench on one side and a ratchet mechanism on the other side. The ring end has a closed loop with a specific size and shape to fit the corresponding fastener. It usually has a 12-point or 6-point configuration to provide a secure grip on the fastener without slipping.

The ratchet mechanism is located at the other end and allows for convenient one-way motion. It enables the user to turn the fastener without having to lift the spanner off the nut or bolt. The ratchet mechanism typically has a switch or lever that allows you to change the direction of rotation, making it useful for both tightening and loosening.

The advantage of using ring ratchet spanners is that they eliminate the need to remove and reposition the spanner for each turn. This makes them particularly useful in tight spaces where a full swing of the spanner is not possible. The ratcheting action enables faster and more efficient work compared to traditional open-end or box-end wrenches.

Ring ratchet spanners come in various sizes to accommodate different fastener dimensions, and they are commonly available in metric or imperial measurements. They are widely used in automotive repair, mechanical engineering, plumbing, and various other applications where fasteners need to be tightened or loosened.

Ratchet Spanners

Showing all 16 results

-

Ratchet Spanners

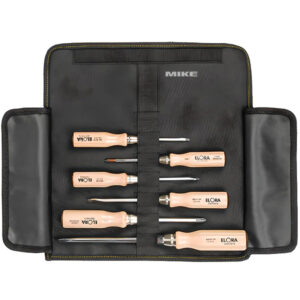

Combination spanner set ELORA 204-S8AFT, ratchet imperial

imperial sizes 5/16 to 3/4 AF, made from Chrome-Vanadium steel with a matte chrome finish. It features a 5° swivel angle and comes in a durable Tetoron rolling pouch with a suspension eye for easy storage and access.

SKU: 204S-8AFT -

Ratchet Spanners

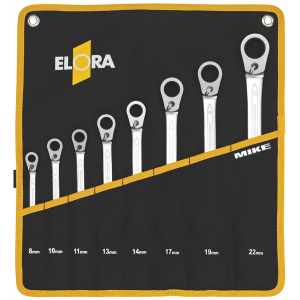

ELORA 204-S8MT Combination Spanner Set with Ring Ratchet

includes sizes 8, 10, 11, 13, 14, 17, 19, and 22 mm, ELORA-Chrome-Vanadium steel with a matte chrome finish. It features a 5° swivel angle, high torque transmission, and comes in a Tetoron rolling pouch with a suspension eye.

SKU: 204-S8MT -

Ratchet Spanners

Reversible ratchet spanner set ELORA 204-JS8MT, Teteron pouch

Includes sizes 8, 10, 11, 13, 14, 17, 19, 22 mm, made from durable Chrome-Vanadium steel, featuring a 5° swivel angle, reversible sides, and compatibility with Adaptors No. 118S4. Packaged in a Teteron rolling pouch.

SKU: 204-J S8MT -

Ratchet Spanners

Combination spanner set ELORA 204-S8M OMS with ring ratchet

Dual-end tools with a minimal 5° swivel angle for high torque transmission. Chrome-Vanadium steel, they are housed in a grease-resistant case with adaptable features for bit-ratchet conversion, ensuring versatility and efficiency.

SKU: 204-S8M OMS -

Ratchet Spanners

ELORA 204-JS8M OMS combination spanner set, ring ratchet

bent ring ratchets with a 5° swivel angle and high torque transmission. Housed in a black metal case with oil-resistant yellow foam, these matte chrome-plated tools use Chrome-Vanadium steel for durability and versatility.

SKU: 204-JS8M OMS -

-

-

-

-

-

Ratchet Spanners

ELORA 204-R S8M combination spanner set, joint ring ratchet

features 180° swivel-type ring sides with a minimal swivel angle of 5°, high torque transmission, and ground heads. Made of ELORA-Chrome-Vanadium steel, matte chrome plated, and adaptable for use as bit-ratchets with ELORA Adaptors No. 118S4.

SKU: 204-RS8M -

-

Ratchet Spanners

Combination spanner ELORA 204- with ring ratchet straight version

The Combination spanner ELORA 204- by Elora, made in Germany, boasts a straight version with an integrated ratchet ring mechanism for efficient and precise tightening and loosening, suitable for tight spaces.

SKU: 204- -

Ratchet Spanners

Combination spanner ELORA 204-J with ring ratchet, reversible

Featuring a game-changing reversible ringside for quick ratcheting direction changes. It boasts high torque capability, a small swivel angle, and durable construction, making it an essential tool for professionals and DIY enthusiasts.

SKU: 204-J -

Ratchet Spanners

Single offset wrenches MCC OW series, Made in Japan

Single offset wrenches, specialized for scaffolding or metal structures construction. The circular head has 12 edges, with a convenient rotation angle of 30 degrees and a high torque. 100% manufactured in Japan with full certification.

SKU: OW -

Ratchet Spanners

Ratchet Wrenches Double Sockets RW, MCC-Made in Japan

A durable, double socket wrench made in Japan. With its unique dodecagon socket design, reversible ratchet action, and extensive size variations, this versatile tool is perfect for precise bolting in construction, electrical, and machinery applications.

SKU: RW-