The production process for the reversible ratchet involves a combination of advanced manufacturing technologies and skilled craftsmanship to ensure consistent quality and reliability. At each stage of the process, strict quality control measures are implemented to guarantee that only the best products are delivered to customers.

ELORA’s production process for the reversible ratchet involves a series of precise and carefully controlled steps, from selecting high-quality raw materials to delivering a finished product that meets the highest standards of quality and durability. Through the use of advanced manufacturing technologies and skilled craftsmanship, ELORA is able to produce ratchets that are both reliable and long-lasting, ensuring customer satisfaction and loyalty.

That our production process for the reversible ratchet is highly automated to achieve consistent quality and efficiency. The following is an overview of the production process:

- Material Selection: High-quality raw materials are selected for the production of the reversible ratchet. Generally, chrome-vanadium steel is used due to its high strength and durability.

- Forging: The raw material is heated to a high temperature and then forged into the basic shape of the ratchet. This process helps to align the grain structure of the material, making it stronger and more durable.

- Machining: The forged blanks are machined to the final shape of the ratchet using precision CNC machines. This process ensures that the dimensions of each ratchet are consistent and within the required tolerances.

- Heat Treatment: The ratchets are then heat-treated to improve their hardness and toughness. This process involves heating the ratchets to a high temperature and then rapidly cooling them to achieve the desired properties.

- Surface Treatment: The ratchets are then subjected to a surface treatment to protect them from corrosion and wear. This may involve plating, coating, or polishing, depending on the specific requirements of the application.

- Assembly and Testing: The individual components of the ratchet, such as the pawl and the drive mechanism, are assembled using automated assembly machines. The finished ratchets are then tested to ensure that they meet the required specifications for torque, durability, and functionality.

- “Marriage” & final assembly: This process involves bringing together the body and internal mechanisms. The handle, internal mechanisms and cover are fitted. The tool’s functionality is thoroughly checked.

- Laser marking: The ratchet is then marked with ELORA logo and product information using a laser marking machine, which ensures the marking is precise and permanent.

- Quality control: Each ratchet undergoes strict quality control measures to ensure it meets the required standards for torque, durability, and functionality. This includes measurement of dimensions, torque testing, and functional testing.

- Packaging and shipping: After passing quality control, the ratchets are carefully packaged and prepared for shipping to customers worldwide. ELORA takes great care to ensure that the products are well-protected during transport to prevent any damage or defects.

Whether you work in precision mechanics or heavy industry, hardly any production facility or workshop today can get by without socket wrenches. And the range of sockets and socket wrenches available from ELORA reflects this broad spectrum of applications. Tradesmen and women appreciate the absolutely dependable quality and the excellent design which ensure long tool lifetimes even under heavy loads.

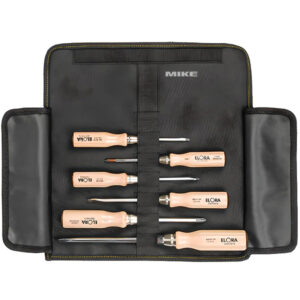

To make certain that this precision tool meets all the requirements expected in industrial environments, a series of production steps are required, as we explain here. You will be impressed by the amount of effort our tool experts put into every tool we make up to the point where it is ready for worldwide shipment and sold to a satisfied customer. This applies to all our products – whether it is a single tool or a complete, carefully compiled tool set.

Reversible Ratchets

Showing all 11 results

-

-

-

Reversible Ratchets

Reversible ratchet ELORA 770-S1U with square driver 3/4 inch

Features a forged gear, minimal swivel angle of 11.25°, and a hot forged, high-pressure I-form handle for high torque. Made from ELORA-Chrome-Vanadium steel, it’s 500mm long, and offers a repair kit option. Made in Germany.

SKU: 770-s1u -

-

-

-

-

-

-

-

Reversible Ratchets

Reversible ratchet 3/8″ ELORA 870-1D, fine tooth, swivel angle 5º

Elora 870-1D reversible ratchet 3/8″ with fine tooth 72 teeth and 5° swivel angle. Forged gear wheel, safety locking, quick release, QUATROLIT®-2C handle, matt chrome-plated surface. Length 200 mm, weight 240 g, supplied with repair kit 870-E1D. Made in Germany.

SKU: 870-1D