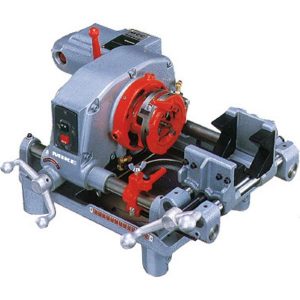

Threading machine REMS Unimat 75, Semi-automatic

SKU: REMS Unimat 75REMS Unimat 75 is a semi-automatic, powerful threading machine with a versatile die head, automatic lubrication, quick-change accessories, and advanced safety features, ideal for industrial threading tasks.

Price from: € 23,700.0 – € 27,800.0

(Price excluding tax, for reference only.)

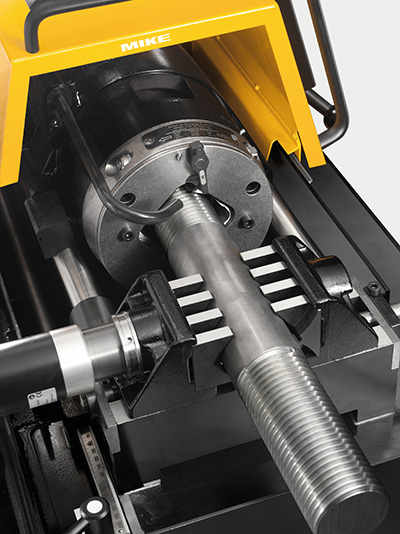

REMS Unimat 75 is a semi-automatic, high-performance threading machine tailored for the efficient cutting of bolt threads ranging from 6 to 72 mm and pipe threads from 1/16 to 2½ inches, making it ideal for heavy industry and metalworking. Its pole-reversible 3-phase induction motor with a hollow shaft, operating at 400 V and 50 Hz with a power output of 2000/2300 W, facilitates both right and left-hand rotation.

This machine stands out with its die head speeds of 70 and 35 rpm, accommodating a wide range of threading tasks. It also features a self-centering universal chuck for a complete clamping range, offering a choice between manual or oil-hydraulic/pneumatic operation modes. The automated lubrication and cooling system ensures the longevity of the machine’s vital components, maintaining the integrity of threads for extended periods.

|

|

Threading machine REMS Unimat 75, Semi-automatic

Each REMS Unimat 75 comes equipped with a universal automatic die head that operates for all thread types, with an automatic open/close function that enhances productivity. The lack of threading sets and a closing lever streamlines the operation, while the electric locking system of the safety cover adds an extra layer of security. For precise adjustments, an adjustment gauge and wrench are included, and the machine is conveniently packaged in a transport case for safe and easy relocation.

list of optional accessories available for purchase for the REMS Unimat 75 threading machine, translated into English:

- Chasers and holders (Threading sets): See page 44 for details.

- Universal automatic die head: Without threading sets, no closing lever – Art.-No. 751000.

- Closing lever: For closing and opening the chasers – Art.-No. 751040.

- R-L: For taper pipe threads, left-hand – Art.-No. 751050.

- G: For cylindrical pipe threads, right-hand – Art.-No. 751060.

- G-L: For cylindrical pipe threads, left-hand – Art.-No. 751070.

- M: For all bolt threads, right-hand – Art.-No. 751080.

- M-L: For all bolt threads, left-hand – Art.-No. 751090.

- Chamfering/Peeling die head 45°: For diameters 7 – 62 mm, with chamfering/peeling chasers 45°, for diameters 7 – 62 mm, HSS, with holder – Art.-No. 751100.

- Chamfering/Peeling die head 45°: For diameters 7 – 62 mm, without threading sets – Art.-No. 751102.

- Chamfering/Peeling chasers 45°: For diameters 7 – 46 mm, HSS, with holder – Art.-No. 751096.

- Chamfering/Peeling chasers 45°: For diameters 40 – 62 mm, HSS, with holder – Art.-No. 751098.

- Chamfering/Peeling chasers 45°: For diameters 7 – 62 mm, pack of 4, with holder – Art.-No. 751097.

- Special clamping jaws: Pair for drawn material, stud bolts and hex screws. Workpiece length protrude from vice without thread, minimum 15 mm, for diameters 6 – 42 mm – Art.-No. 753240.

- Thread-Cutting oil: REMS Spezial, REMS Sanitol.

- Nipple holder.

- REMS herkules material supports.

The basic configuration of the REMS Unimat 75 threading machine includes

- A semi-automatic threading machine for bolt threads from 6 – 72 mm (¼ – 2¾”) and pipe threads from 1/16 – 2½” (16 – 63 mm).

- The machine is mounted on a stand for stability.

- It features a pole-reversible 3-phase induction motor with a hollow shaft, designed for 400 V, 50 Hz, delivering 2000/2300 W for powerful and versatile operation.

- The machine allows right and left-hand rotation with a die head speed of 70 and 35 rpm.

- A self-centering universal chuck is included for the complete clamping range, offering options for manual or oil-hydraulic/pneumatic operation.

- An automatic lubrication and cooling system is integrated for the longevity of the machine.

- It comes with one universal automatic die head that works for all thread types, which opens and closes automatically.

- The machine is sold without threading sets and without a closing lever.

- It has an electric locking system for the safety cover.

- An adjustment gauge and wrench are included for precise setup.

- The REMS Unimat 75 is packaged in a transport case for convenience and mobility.

Choosing the right REMS Unimat 75 threading machine

When selecting a REMS Unimat 75 threading machine, consider the following steps to find the perfect fit for your needs:

- Assess your thread requirements:

- Determine the range of bolt and pipe thread sizes you plan to work with, ensuring the machine accommodates threads from 6 mm to 72 mm for bolts and 1/16 inch to 2½ inches for pipes.

- Consider the work environment:

- Verify that the electrical specifications, such as voltage and frequency (400 V, 50 Hz), are compatible with your facility’s power supply.

- Evaluate operation modes:

- Decide if you need a manual clamping device for flexibility or an oil-hydraulic/pneumatic vice for speed and consistency, especially for high-volume threading tasks.

- Understand the die head mechanism:

- Ensure the universal automatic die head meets your threading needs, offering automatic opening and closing for efficient operation.

- Check additional features:

- Look for machines with an automatic lubrication and cooling system to enhance the longevity of the machine and maintain thread quality.

- Safety considerations:

- The electric locking system for the safety cover is a crucial feature, offering an extra layer of protection during operation.

- Portability:

- If relocation is a possibility, consider if the transport case option is a necessity for your operations.

By taking these factors into account, you’ll be able to choose a REMS Unimat 75 model that not only meets your threading demands but also fits seamlessly into your workflow, maximizing efficiency and safety.

| SKU | Price | Add | Set name |

|---|---|---|---|

| 750003 | € 23,700.0 | Manual clamping | |

| 750004 | € 27,800.0 | Oil hydraulic/pneumatic vice clamping |

- Pending orders

Accessories and options

| SKU | Price | Add | Thumbnail | Products |

|---|---|---|---|---|

| Nippelfix | Price on request |  |

REMS Nippelfix accessories for threading machines

Automatic internal clamping chuck for threading short pipe pieces up to 4″. Quick, tool-free operation, efficient production, internal clamping mechanism, durable clamping. REMS – Made in Germany. |

|

| Nippelspanner | € 110.0 – € 342.0 | Select |  |

REMS Nippelspanner accessories for threading machines

Nippelspanner is a manual pipe nipple chuck designed for internal clamping of short pipe pieces. Compatible with various threading machines, it saves time and money by utilizing short pipes efficiently. REMS – Germany. |

| REMS Sanitol | € 22.0 – € 1,564.0 | Select |  |

REMS Sanitol Thread-cutting oil, made in Germany

mineral oil-free thread-cutting oil, ideal for drinking water pipes and universal threading. Water-soluble, ethanol-free, and featuring high lubrication and cooling effects, it ensures clean threads and longevity of tools. |

| REMS Spezial | € 20.0 – € 630.0 | Select |  |

REMS Spezial thread-cutting oil, made in Germany

REMS Spezial, an eco-friendly thread-cutting oil, enhances threading with superior lubrication and cooling, extends tool lifespan, and meets environmental standards for safe use on drinking water pipes. Made in Germany. |

- Pending orders