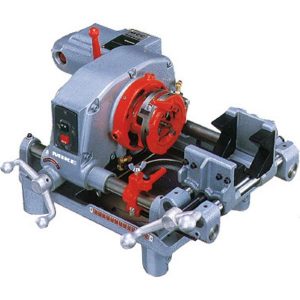

REMS Magnum threading machine up to 3″, made in Germany

SKU: Magnum 3REMS Magnum is a high-performance threading machine for ½ – 3″ pipes, featuring maintenance-free operation, a safety foot switch, automatic lubrication, versatile die heads, and a choice of three motors.

Price from: € 5,971.0 – € 8,731.0

(Price excluding tax, for reference only.)

REMS Magnum Threading Machine up to 3 inches is a robust, multifunctional device designed for threading, cutting, deburring, and roll grooving tasks. It features a maintenance-free gear system that operates within a sealed oil bath, ensuring continuous high performance without the need for regular upkeep. The machine is equipped with a safety foot switch featuring an emergency stop function, enhancing operator safety during use.

The self-tightening quick-action hammer chuck prevents pipe slippage, ensuring secure clamping, particularly for long pipes. This is complemented by a rear centering device for precise material alignment. REMS Magnum also boasts an automatic lubrication and cooling system that maintains clean threads and extends the life of the dies, tools, and the machine itself.

|

|

|

| REMS 380304 & 344150 | REMS 380304 & 344100 | REMS 380304 & 344105 |

REMS Magnum threading machine up to 3″

With a complete set of tools for threading ranges from 1/16 to 2 inches and/or 2½ to 3 inches, each set includes a universal automatic die head suitable for all thread types, including long threads, and an automatic opening feature with an automatic thread-length stop for tapered threads. The dies cater to pipe threads and are made from high-quality, specially tempered, and hardened steel, ensuring durability.

Customers can choose from three powerful motor options to suit various operational needs. The L-T version features a removable large oil basin and chip tray for ease of cleaning and portability, while the T version has an integrated, larger oil basin and chip tray for a more permanent setup.

Both versions are designed for convenience, whether for use on a workbench, with a stand, or with a collapsible wheel stand that includes a material shelf for optimal work height and stability. Each machine is packaged in a carton for secure transport and storage.

The basic configuration of the REMS Magnum 3-inch

threading machine includes:

- Capability for threading pipes from ½ to 3 inches and bolts from 18 to 60 mm.

- A maintenance-free gear system operating in a sealed oil bath.

- A safety foot switch with an emergency stop function.

- A self-tightening quick-action hammer chuck for secure, slip-free pipe clamping.

- A rear centering device for precise material alignment.

- Automatic lubrication and cooling systems to ensure clean threads and extended tool life.

- Comprehensive tool sets for 1/16 – 2″ and 2½ – 3″ threading, featuring a universal automatic die head for all thread types, including an automatic thread-length stop for tapered threads.

- A choice of three powerful motor options.

- The L-T version offers portability with a removable large oil basin and chip tray.

- The T version is designed for stationary use with an integrated, larger oil basin and chip tray.

- Designed for ease of transport and optimal stability on a workbench or with a stand.

- All packaged in a carton for delivery and storage.

Guide to selecting the right REMS Magnum 3-Inch Threading Machine

When selecting the REMS Magnum 3-inch threading machine, consider the following guidelines to ensure you choose the right model for your needs:

- Power Supply Compatibility:

- Verify your workshop’s available power supply and choose a model that matches the voltage requirements, whether it’s 230 V, 110 V, or 400 V.

- Motor Selection:

- Assess the demand of your threading tasks. If you require a robust power output, consider a motor with higher wattage.

- For quieter operations and varied speed requirements, look at models offering two-speed motors with overload protection.

- Portability vs Stationary Setup:

- Decide if you need the machine to be portable (L-T version) with a removable oil basin and chip tray, or if a stationary setup (T version) with an integrated basin suits your workspace better.

- Thread Range Requirement:

- Ensure the machine supports the range of thread sizes you plan to work with, both for pipes and bolts.

- Die Head and Dies:

- The machine should come with a universal automatic die head that caters to all your threading requirements, including the facility for automatic opening and a thread-length stop for tapered threads.

- Additional Features:

- Look for features that improve efficiency, like self-tightening chucks for pipe slippage prevention and rear centering devices for material alignment.

- Accessories and Toolsets:

- Check if the machine comes with a full set of dies and tools for the range of work you plan to undertake.

- Safety Features:

- Don’t overlook safety features such as the emergency-stop function on the foot switch.

- Maintenance and Longevity:

- Opt for models with automatic lubrication and cooling systems to prolong the lifespan of the machine and tooling.

- Product Code Identification:

- Take note of the product code (Art.-No.) for the specific version you decide upon, to ensure accurate ordering and service in the future.

By considering these factors carefully, you’ll be able to select a REMS Magnum 3-inch threading machine that will meet the specific needs of your projects and provide reliable service for years to come.

| Description | Set name | Engine | Power source | Wattage | Equipment | Art.-No. |

|---|---|---|---|---|---|---|

| 3000 L-T | L-T | Universal | 230V/110V, 50Hz |

1700W. 23 rpm |

R 2½ –3 R ½ – 3 |

380303 380309 |

| 3010 L-T | L-T | Polereversible capacitor | 230V, 50 Hz |

2100W. 20/10 rpm |

R 2½ – 3 R ½ – 3 |

380304 380310 |

| 3020 L-T | L-T | Polereversible 3~ induction | 400V, 50 Hz |

2000W. 20/10 rpm |

R2½ – 3 R ½ – 3 |

380305 380311 |

| 3000 T* | T* | Universal | 230V/110V, 50Hz |

1700W. 23 rpm |

R 2½ –3 R ½ – 3 |

380306 380312 |

| 3010 T* | T* | Polereversible capacitor | 230V, 50 Hz |

2100W. 20/10 rpm |

R 2½ –3, R ½ – 3 |

380307 380313 |

| 3020 T* | T* | Polereversible 3~ induction | 400V, 50 Hz |

2000W. 20/10 rpm |

R 2½ – 3, R ½ – 3 |

380308 380314 |

| SKU | Price | Add | Set name | Power | Pipe threads |

|---|---|---|---|---|---|

| 380303 | € 5,971.0 | L-T | 230V/110V - 50Hz - 1700W | 2½ - 3 | |

| 380309 | € 7,295.0 | L-T | 230V/110V - 50Hz - 1700W | ½ - 3 | |

| 380304 | € 6,255.0 | L-T | 230V - 50Hz - 2100W | 2½ - 3 | |

| 380310 | € 7,582.0 | L-T | 230V - 50Hz - 2100W | ½ - 3 | |

| 380305 | € 6,517.0 | L-T | 400V - 50Hz - 2000W | 2½ - 3 | |

| 380311 | € 7,840.0 | L-T | 400V - 50Hz - 2000W | ½ - 3 | |

| 380306 | € 6,858.0 | T* | 230V/110V - 50Hz - 1700W | 2½ - 3 | |

| 380312 | € 8,186.0 | T* | 230V/110V - 50Hz - 1700W | ½ - 3 | |

| 380307 | € 7,146.0 | T* | 230V - 50Hz - 2100W | 2½ - 3 | |

| 380313 | € 8,469.0 | T* | 230V - 50Hz - 2100W | ½ - 3 | |

| 380308 | € 7,407.0 | T* | 400V - 50Hz - 2000W | 2½ - 3 | |

| 380314 | € 8,731.0 | T* | 400V - 50Hz - 2000W | ½ - 3 |

- Pending orders

Accessories and options

| SKU | Price | Add | Thumbnail | Products |

|---|---|---|---|---|

| 3414- | € 405.0 – € 610.0 | Select |  |

REMS Die set for universal automatic die head 1/16 – 2 inch REMS

|

| Nippelspanner | € 110.0 – € 342.0 | Select |  |

REMS Nippelspanner accessories for threading machines

Nippelspanner is a manual pipe nipple chuck designed for internal clamping of short pipe pieces. Compatible with various threading machines, it saves time and money by utilizing short pipes efficiently. REMS – Germany. |

| REMS Sanitol | € 22.0 – € 1,564.0 | Select |  |

REMS Sanitol Thread-cutting oil, made in Germany

mineral oil-free thread-cutting oil, ideal for drinking water pipes and universal threading. Water-soluble, ethanol-free, and featuring high lubrication and cooling effects, it ensures clean threads and longevity of tools. |

| REMS Spezial | € 20.0 – € 630.0 | Select |  |

REMS Spezial thread-cutting oil, made in Germany

REMS Spezial, an eco-friendly thread-cutting oil, enhances threading with superior lubrication and cooling, extends tool lifespan, and meets environmental standards for safe use on drinking water pipes. Made in Germany. |

- Pending orders