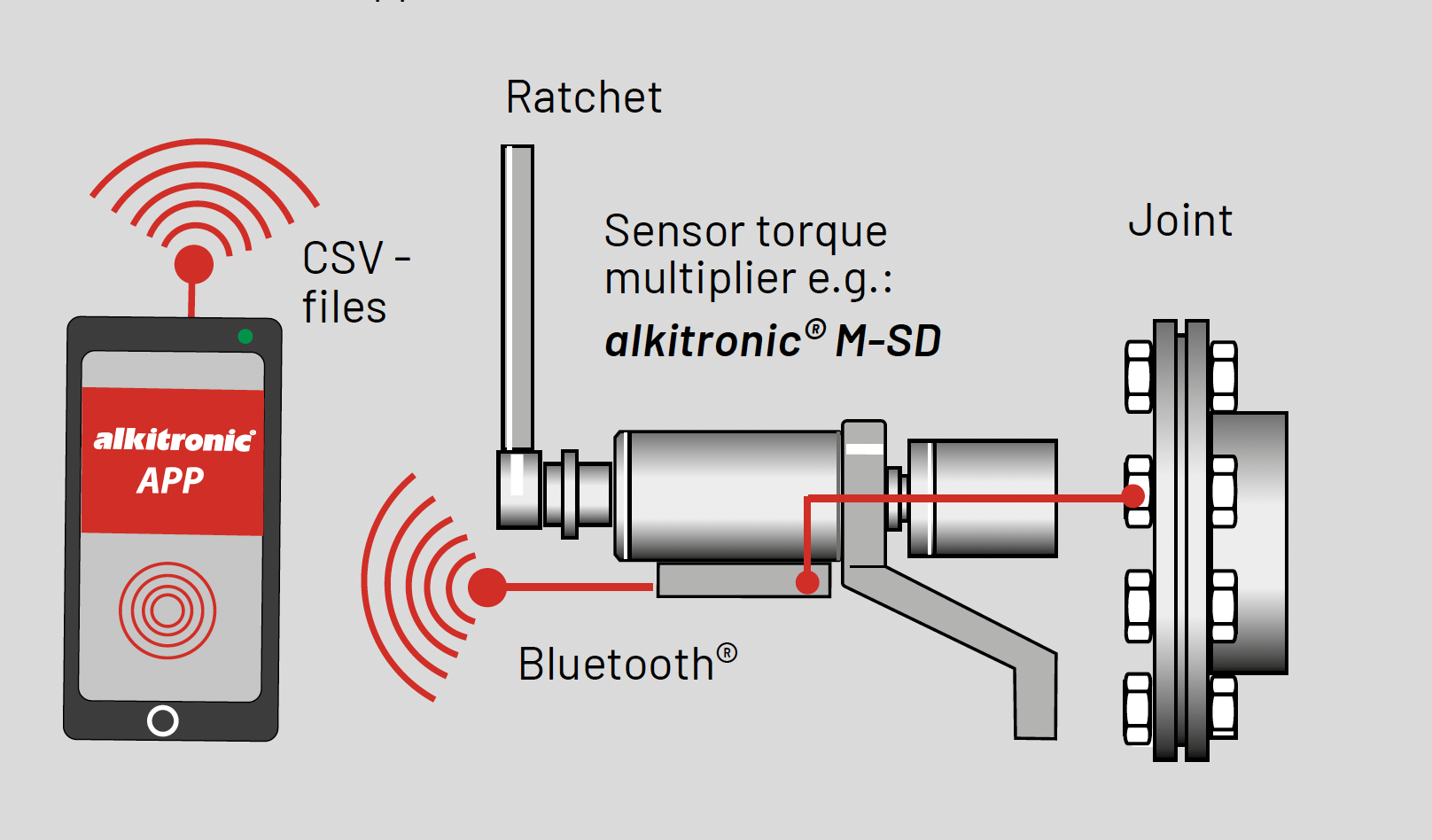

The alkitronic® Mounting Documentation Systems (MDS) are designed to enhance the precision and traceability of bolt connections, crucial in high-quality bolting scenarios. This system includes the , a manually operated torque multiplier, and the alkitronic® PC-SD, which operates pneumatically. Both models ensure torque-controlled bolting with reliable, on-the-spot data recording.

Key Features of alkitronic® MDS:

- Traceability and Documentation: Ensures compliance with legal regulations and international quality standards by providing traceable bolting parameters and documentation to the end-user.

- On-site Torque Setting and Recording: Operators can set and record torque values directly at the work site, which is displayed on an OLED panel in Nm or ft.lbs.

- Data Transmission and App Integration: Features Bluetooth connectivity for seamless data transmission to mobile devices and uses the alkitronic® APP for efficient data handling and recording.

- Robust and Reliable Tools: The M-SD model is designed for high mobility without needing an external power supply, whereas the PC-SD features a robust cast aluminum motor housing and high-performance gears for minimal wear and high load management.

Mounting Documentation Systems Alkitronic MDS

- Safety and Precision: The system ensures optimized process safety and work safety, with guaranteed traceability of bolted joints. The torque multipliers come with pre-set programs that allow for various bolting and measurement methods, enhancing operational efficiency and precision.

- User-Friendly Interface: Both models support multilingual menu-guided operation, augmented by visual and acoustic control or warning signals, making it user-friendly and reducing the risk of operational errors.

- Versatile Applications: Suitable for diverse industrial applications, these systems cater to environments requiring precise torque and rotation settings, such as in manufacturing plants, automotive assembly, and heavy machinery maintenance.

|

|

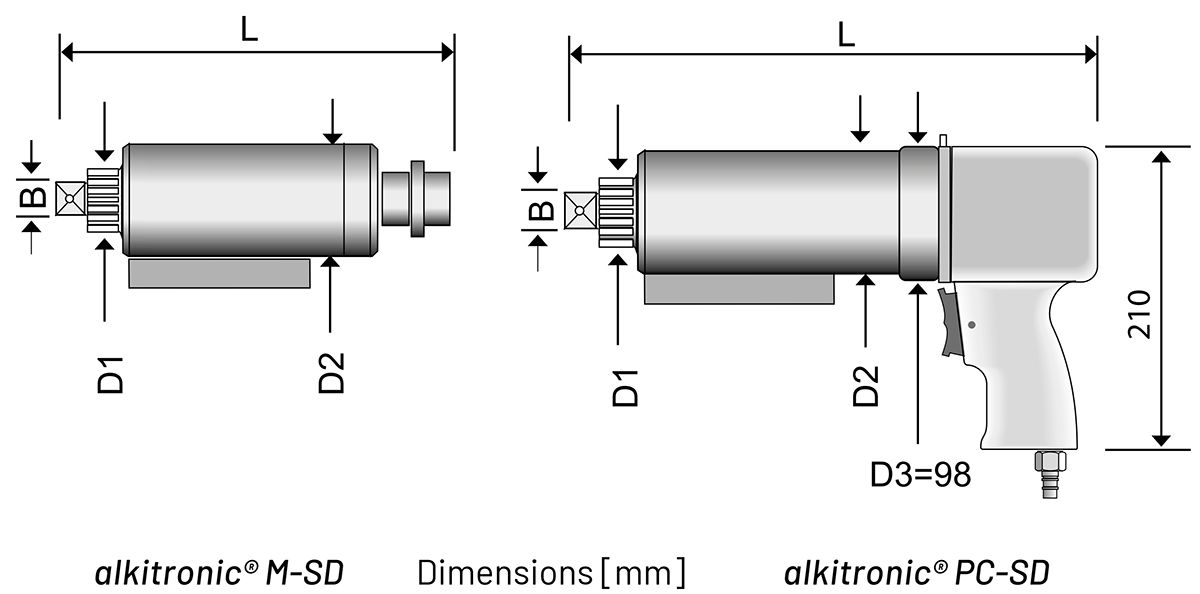

| alkitronic® M-SD | alkitronic® PC-SD |

Technical Specifications and Benefits:

- Measurement Accuracy: Offers a high accuracy rate (+/- 1%) and operates effectively within a temperature range of 0 to +50°C.

- Program Options: Includes multiple operational programs like torque controlled bolting, bolt quality control, torque checking, and determination of required angles for testing and development.

This documentation system not only ensures high-quality bolt connections but also contributes to enhanced productivity and precision in industrial bolting applications, supported by German engineering and decades of experience in bolting technology from alkitronic®.

alkitronic® Mounting Documentation Systems:

| Model | Torque Range (Nm) |

Power (Nm) | Square Drive | Diameter D1 (mm) |

Diameter D2 (mm) |

Length (mm) | Weight (kg) | Idle Speed (r/min) |

|---|---|---|---|---|---|---|---|---|

| M-SD100 | 100-1000 | 1000 | 1” | 54 | 88 | 220 | 6.4 | – |

| M-SD200 | 200-2000 | 2000 | 1” | 54 | 88 | 295 | 7.6 | – |

| M-SD400 | 400-4000 | 4000 | 1½” | 72 | 98 | 320 | 11.35 | – |

| PC-SD100 | 100-1000 | 1000 | 1” | 54 | 88 | 360 | 10 | 11 |

| PC-SD200 | 200-2000 | 2000 | 1” | 54 | 88 | 390 | 11.25 | 5 |

| PC-SD400 | 400-4000 | 4000 | 1½” | 72 | 98 | 410 | 15 | 3.5 |

This table provides a concise overview of the specifications for each variant in the alkitronic® MDS product line.

Technical features of the alkitronic® M-SD series:

- Torque Range: Offers a comprehensive range from 100 to 4000 Nm, suitable for various tightening requirements.

- Manual Operation: Allows for independence from external power sources, enhancing mobility.

- Precision: High repeatability in tightening, ensuring consistent performance regardless of external disturbances.

- User Interface: Features a control panel with an OLED display for clear visibility of torque settings in Nm or ft.lbs.

- Torque/Torque Angle Procedure: Manual setting and documentation on site for detailed control and traceability.

- Compact Design: Ergonomic dimensions and lighter weight make it easy to handle and operate in various settings.

- Robust Construction: Designed for durability with high-quality materials to withstand rigorous industrial use.

Technical features of the alkitronic® PC-SD series

- Torque Range: Capable of handling 100 to 4000 Nm, ideal for a variety of industrial applications.

- Pneumatic Operation: Features a proven pneumatic drive which enhances reliability and performance in demanding environments.

- Robust Motor Housing: Constructed from cast aluminum for increased durability and longevity.

- High-Performance Gears: Utilizes chip-free, high-precision manufacturing processes to handle high loads with minimal wear.

- Simple Operation: Designed for easy one-finger operation for both right and left rotations, increasing user convenience.

- Torque Recording: Equipped with sensors directly on the square drive for accurate torque recording and monitoring.

- Data Communication: Offers Bluetooth interface for seamless data transmission to mobile devices, supporting efficient workflow management.

- Multilingual Menu-Guided Operation: Enhances user experience with visual and acoustic signals for control and alerts, making it adaptable for international use.