Geared trolley single bar TGS series – Tiger Lifting

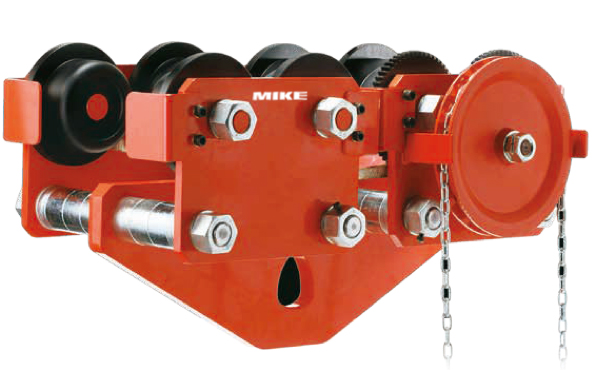

SKU: TGSprovides reliable load handling with anti-drop safety features, corrosion and spark-resistant options, and smooth, low-maintenance rolling on sealed bearings. Suitable for various industrial environments.

Price from: € 150.0 – € 800.0

(Price excluding tax, for reference only.)

Geared Trolley TGS series from Tiger Lifting is designed to meet demanding lifting and transportation needs. Providing a robust solution for applications that require precise load handling along beams. Manufactured to meet and exceed BS EN 13157: 2004+A1:2009 and AS1418.2 standards, the TG series trolleys are reliable, durable, and well-suited for various industrial settings.

With a load capacity range from 0.5 to 35.0 tonnes, the TGS geared trolleys are engineered for versatility. Their anti-drop plate design adds a crucial layer of safety by protecting the wheels when they make contact with end rail stoppers.

|

|

Additionally, the trolley wheels feature a convex profile, which helps to distribute load stresses more evenly, thus eliminating potential point loading. These wheels operate on sealed bearings, ensuring smooth rolling that requires minimal effort and lowers maintenance needs.

Geared Trolley Product Information

| Product Code |

Capacity (tonne) |

D – Track | Min. curve radius (m) |

Net Weight (kg) |

||

|---|---|---|---|---|---|---|

| Range 1 (mm) |

Range 2 (mm) |

Range 3 (mm) |

||||

| TGS-0050 | 0.5 | 62-128 | 62-203 | 140-310 | 0.8 | 9.0 |

| TGS-0100 | 1.0 | 62-128 | 62-203 | 142-310 | 1.0 | 11.0 |

| TGS-0200 | 2.0 | 88-154 | 88-230 | 194-310 | 1.3 | 16.5 |

| TGS-0300 | 3.0 | 87-153 | 87-230 | 193-310 | 1.5 | 24.5 |

| TGS-0500 | 5.0 | 106-194 | 106-305 | – | 1.5 | 35.5 |

Geared trolley single bar TGS can be configured for single or twin bar designs. For those needing precise control, the geared option provides easy hand-chain operation, with the standard chain length set at 2.5 meters, although custom lengths can be ordered to suit specific application needs.

Geared trolley single bar TGS series

Load capacity from 0.5 to 35.0 tonnes – Tiger Lifting

The trolley’s universal wheels are powder-coated for added durability and can accommodate both tapered and flat flange beams, making them adaptable across various beam types and flange widths.

- Meets BS EN 13157: 2004+A1:2009 and AS1418.2 standards.

- Load capacity from 0.5 to 35.0 tonnes.

- Anti-drop plate design protects wheels at rail end stops.

- Convex wheel profile prevents point loading.

- Wheels run on sealed bearings for smooth, low-maintenance operation.

- Available in single or twin bar configurations.

- Standard hand chain length of 2.5m, customizable on request.

- Universal wheels fit both flat and tapered flange beams.

- Corrosion-resistant and spark-resistant versions available.

- Operating temperature from -40°C to +80°C (extended to -60°C on request).

- 5:1 safety factor, compatible with manual or powered hoists.

- Optional beam locking device available.

For challenging environments, Tiger offers both corrosion-resistant and spark-resistant versions of the Geared trolley single bar TGS. The corrosion-resistant model is designed for long-term reliability in corrosive settings. Critical components like the hand chain and pinion gear are protected by the Organic Compound Protection (OCP) finish.

Which, along with stainless steel fittings, maintains the trolley in near-new condition and reduces inspection time for re-certifications. The trolley is finished in a high-quality white Akzo Nobel powder coat for added corrosion and impact resistance.

Features and benerfit

In applications where spark resistance is essential, the Geared trolley single bar TGS meets ATEX Directive 94/9/EC standards for use in explosive zones. This version features solid bronze wheels, rubber buffers, and copper-plated components, all designed to minimize spark risk in gas and dust hazardous areas (Zones 1 & 2 for gas, Zones 21 & 22 for dust).

This construction makes it highly suitable for industries with strict safety requirements, providing reliable performance even in challenging environments. Geared trolley single bar TGS series also offers optional features, such as an extended beam width and a beam locking device for added security.

The 5:1 factor of safety allows the trolley to be used confidently with both manual and powered hoists across its operating temperature range of -40°C to +80°C, with an extended option of -60°C to +80°C for extreme conditions.

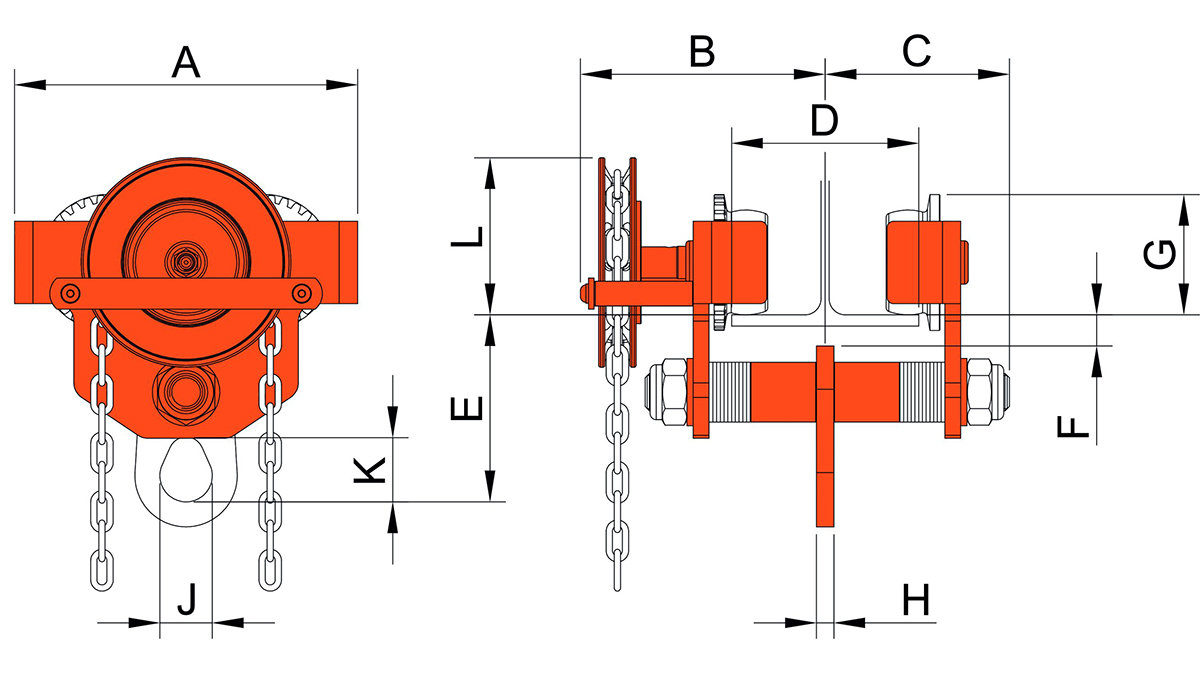

Geared Trolley Dimensions

Each Geared trolley single bar TGS unit comes fully certified with a test certificate or EC Declaration of Conformity, ensuring compliance with the essential health and safety requirements outlined in the Machinery Directive 2006/42/EC.

| Product Code | A | A+ | B | C | E | F | G | H | J | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|

| TGS-0050 | 195 | 235 | 180 | 106 | 98 | 20 | 64 | 10 | 24 | 30 | 79 |

| TGS-0100 | 213 | 253 | 180 | 113 | 106 | 20 | 71 | 10 | 28 | 34 | 82 |

| TGS-0200 | 236 | 284 | 195 | 136 | 132 | 25 | 80 | 12 | 38 | 45 | 94 |

| TGS-0300 | 275 | 323 | 198 | 146 | 150 | 25 | 97 | 13 | 42 | 52 | 126 |

| TGS-0500 | 323 | 371 | 216 | 169 | 174 | 30 | 117 | 16 | 46 | 60 | 137 |

(Unit: mm)

This documentation guarantees the product’s safety and dependability for industrial use, offering reassurance to operators handling loads in diverse and often hazardous environments.

| SKU | Price | Add | pa_duong-kinh-mm | Track width |

|---|---|---|---|---|

| TGS-0050 | € 150.0 | R1:62-128, R2:62-203, R3:140-310 | ||

| TGS-0100 | € 190.0 | R1:62-128, R2:62-203, R3:142-310 | ||

| TGS-0200 | € 420.0 | R1:88-154, R2:88-230, R3:194-310 | ||

| TGS-0300 | € 500.0 | R1:87-153, R2:87-230, R3:193-310 | ||

| TGS-0500 | € 800.0 | R1:106-194, R2:106-305 |

- Pending orders