Insulated tools from ELORA are produced in Germany and comply with IEC safety standards. Each tool undergoes individual testing at 10,000 V AC. They are approved for safe work up to 1,000 V AC or 1,500 V DC. This ensures reliability when used in demanding electrical applications where worker safety is critical. The strict testing confirms consistent insulation quality across the full range of insulated tools.

Testing covers voltage resistance, impact, adhesion, fire resistance, and compression. The insulation withstands impact after storage at -25 °C and +23 °C. Adhesion tests use a 500 N tensile force after 168 hours at 70 °C. Fire resistance is verified by 10 seconds of direct flame exposure with flame spread limited under 120 mm. Compression tests apply 20 N combined with 5,000 V AC for three minutes without discharge.

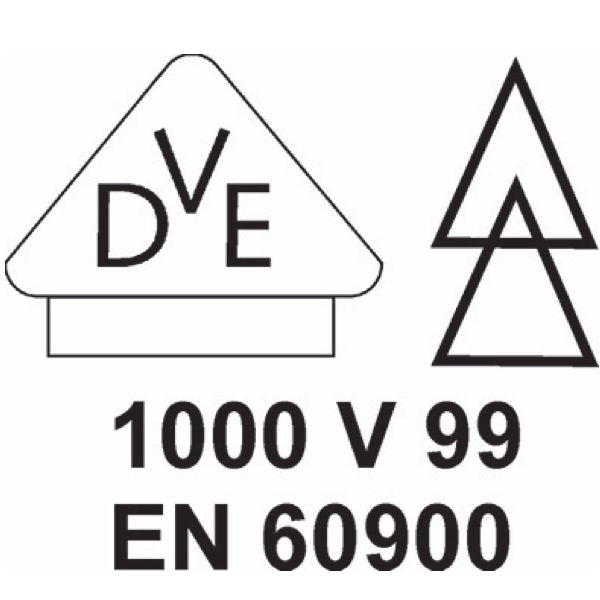

All tools carry the VDE GS mark and double triangle symbol. These markings confirm compliance with harmonised safety standards for live electrical systems. ELORA insulated tools deliver proven safety for electricians and technicians. They ensure consistent performance in electrical work, industrial maintenance, and energy applications. Reliable insulation reduces the risk of accidents and supports long-term professional use.

Insulated tools are totally difference to conventional tools. Please follow some special icon marked on tool below to identified.

|

|

|

This symbol indicates that the tools so marked have been tested for safety regarding potential hazards from electricity, physical danger, heat, radiation and other hazards. The symbol is equivalent to the German VDE requirements and comparable with harmonised standards in the EU and around the world and confirms that the defined tolerance limits have been adhered to.

Double triangle and voltage range

Markings for insulated tools consisting of the double triangle show their suitability for work on electrical systems that are still “live”. The voltage or voltage range given shows the maximum safe load in volts.

Insulated tools ELORA – Made in Germany

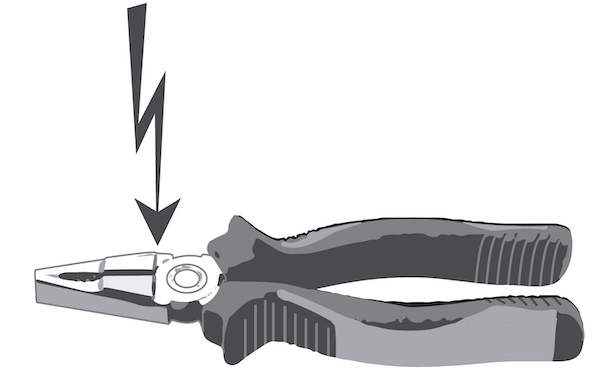

Safety checks to IEC standards using a pair of ELORA pliers as an example

1. Voltage test: ELORA VDE tools are individually tested to 10,000 V AC and are approved for work in systems carrying a live voltage of up to 1,000 V AC or 1,500 V DC.

|

|

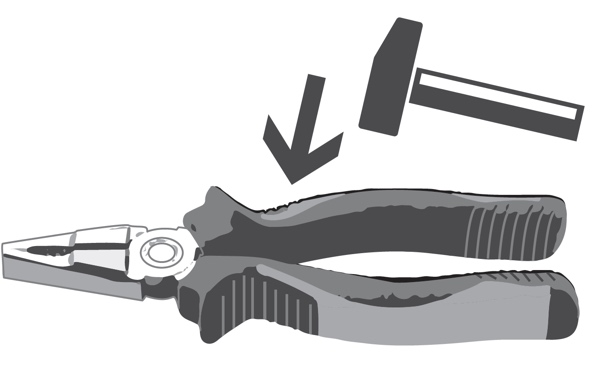

2. Impact test for isulated tools: The insulating material of ELORA VDE tools is subjected to an impact test. At an ambient temperature of +23 °C and after storage for 2 hours at -25 °C, an impact test is performed to see whether the insulation material can withstand jolts and impacts after being subjected to these fluctuations in temperature. The test must not cause any of the insulation to crack, rupture or peel off.

|

|

|

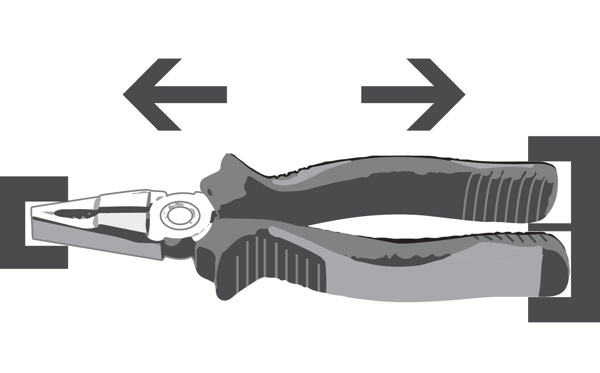

3. Adhesion test: Even under high loads, the insulation material must remain firmly bonded to the tool. First, the tool is stored for 168 hours at a temperature of 70 °C. Then the adhesive strength of the insulation material is subjected to a tensile force of 500 N.

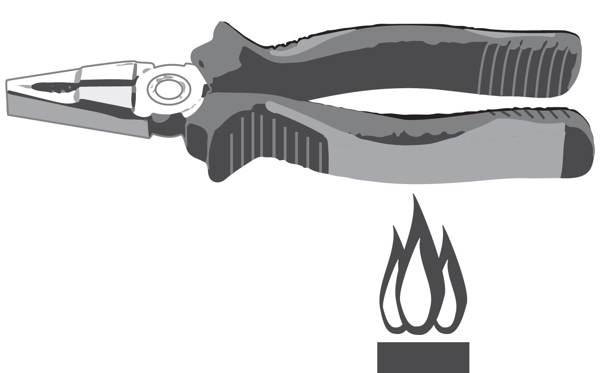

4. Testing resistance to fire: A test flame is aimed at the tool for a duration of 10 seconds. Once the flame is removed, the flame emitted by the insulation must not exceed 120 mm for a period of 20 seconds.

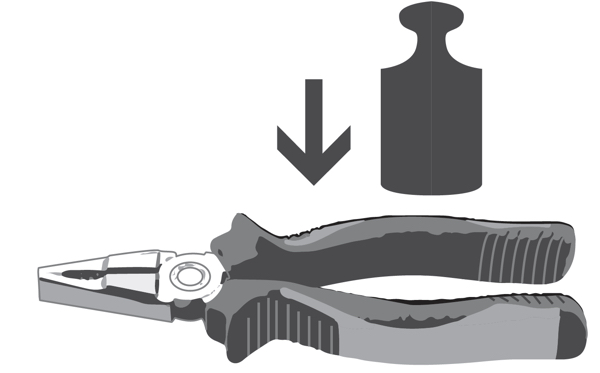

5. Pressure test: After being stored for 2 hours at 70 °C, the insulation material of the ELORA VDE tools is subjected to a compressive force of 20 N and a testing voltage of 5,000 V AC for three minutes. During this time, there must be no disruptive discharge or arcing on the surface or in the air.

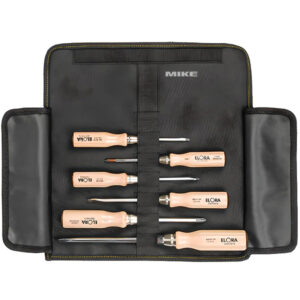

Insulated Tools

Showing all 20 results