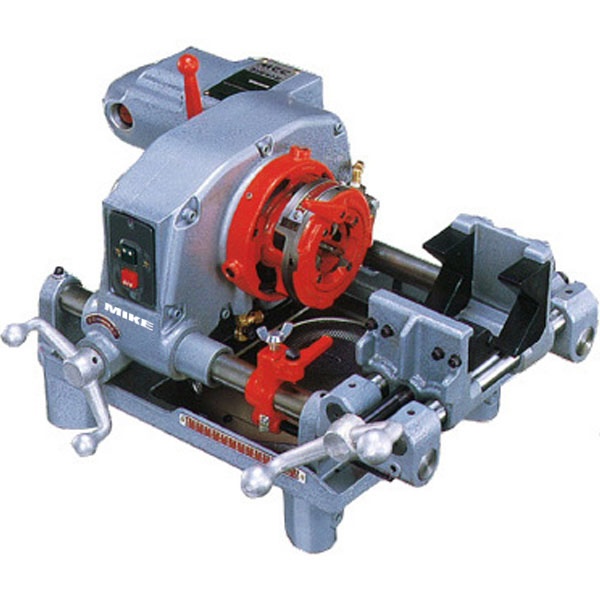

Conduit pipe threading machine CM82, MCC made in Japan

Available on backorder

Offers precision threading for C15-C75 (JIS Conduit) and PF1/2-PF3 (BSPP). Powered by a single-phase 750W motor, adaptable to local voltage. It comes with standard accessories for seamless operation, including die heads, dies, cutting oil, and tools.

Available on backorder

Conduit pipe threading machine CM82, crafted by MCC in Japan, epitomizes efficiency and precision in threading operations. Designed to meet the demands of industrial and professional settings, the CM82 boasts a comprehensive set of features tailored to enhance productivity and reliability.

CM82 excels in threading conduit pipes, offering unparalleled performance and versatility. With its robust single-phase motor and adaptable rotation speeds, it effortlessly handles a wide range of conduit sizes with precision and efficiency. The inclusion of standard accessories such as die heads, dies, cutting oil, and tools ensures seamless operation and convenience for users.

Compact yet powerful, the CM82 weighs 40kg and features dimensions of 460(L) x 350(W) x 280(H) mm, making it ideal for both workshop and on-site usage. It comes equipped with a comprehensive set of standard accessories, including CM Die Head A Type for various sizes, dies, cutting oil, chip scraper, spanner, release bar, hex keys, carbon brush, machine cover, tool box, and legs.

Conduit pipe threading machine CM82

With its robust specifications, the CM82 boasts a capacity to handle C15-C75 (JIS Conduit) and PF1/2-PF3 (corresponding BSPP), supported by a single-phase 750W 50/60Hz series motor adaptable to various local voltage requirements. It operates at two rotation speeds: 40 rpm and 110 rpm without load, ensuring versatility for different threading needs.

CM82 Conduit Pipe Threading Machine, proudly manufactured in Japan by MCC, stands as a pinnacle of precision and efficiency in threading operations tailored specifically for conduit building applications.

Specifications

The CM82 offers seamless operation with its die head rotating solely in forward directions, facilitating quick and effortless threading tasks. Its one-touch changeable die head and easy setting dies ensure efficient workflow and minimize downtime.

- Model: CM82

- Capacity: C15-C75 (JIS Conduit), PF1/2-PF3 (corresponding BSPP)

- Motor: Single phase 750W 50/60Hz series motor, adaptable to local voltage

- Rotation Speed: Two options: 40 rpm and 110 rpm without load

- Weight: 40kg

- Dimension: 460(L) x 350(W) x 280(H) mm

Designed for high-speed and high-efficiency performance, the CM82 features an automatic oiling system that delivers lubrication directly to the dies and bolts during threading operations, enhancing both productivity and tool longevity. Additionally, the die head opens automatically when a desired thread length is pre-set, further streamlining the threading process.

Standard accessories

As a testament to its quality and reliability, the CM82 is proudly labeled as “100% Made in Japan,” embodying the renowned craftsmanship and engineering excellence associated with Japanese manufacturing.

- CM Die Head A Type: C15-51, PF1/2-1.1/2 (1 set)

- CM Die Head A Type: C63-75, PF1-PF3 (1 set)

- Dies: C19-C31, C39-C51, C63-75 (each 1 set)

- Dies: PF1/2-PF3/4, PF1-PF1.1/2, PF2-PF3 (each 1 set)

- Cutting Oil 4 liter can (1pc)

- Chip Scraper (1pc)

- Spanner for die head (1pc)

- Release Bar for die head (1pc)

- Hex Key 3, 4, 5, 6mm (each 1 pc)

- Carbon Brush (1 pc)

- Machine Cover (1 pc)

- Tool Box (1 pc)

- Legs (1 set)

Crafted with meticulous attention to detail and backed by MCC’s reputation for quality craftsmanship, the CM82 is a reliable and indispensable tool for professionals in various industries. Whether it’s electrical installations, plumbing projects, or industrial applications, the CM82 stands ready to deliver exceptional results, making it the preferred choice for threading operations worldwide.