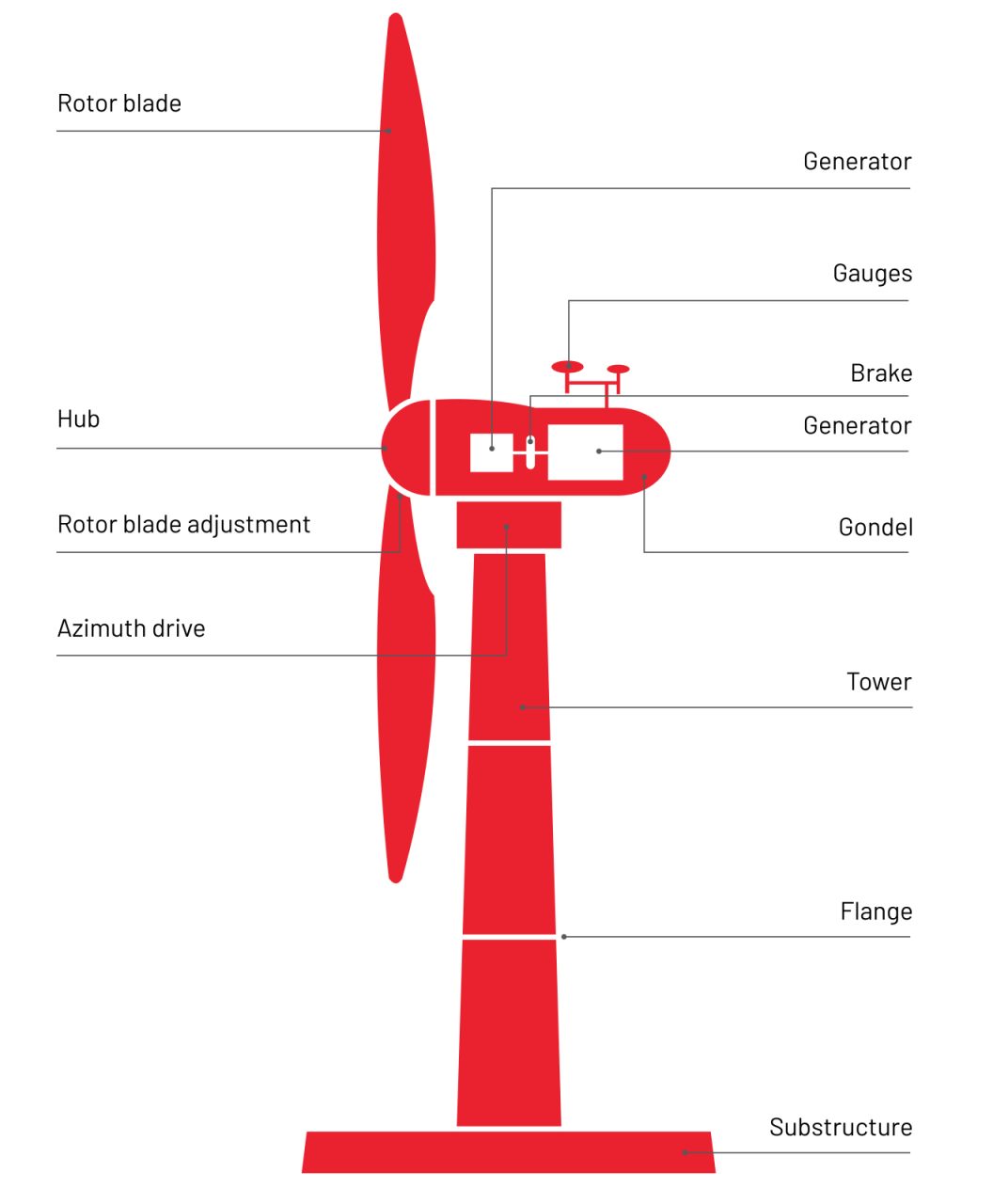

Wind turbines need to withstand high environmental impact. Many tons of weight must be held at lofty heights with absolute reliability. Especially under extreme forces or weather conditions, highly precise, wind-proof bolting techniques are crucial for success. The alkitronic® product range is characterised by complete system solutions for bolted connections in wind turbines.

Selected bolting processes on wind turbines.

THE DRIVING FORCE FOR WIND ENERGY

We know your applications and your bolting processes best. alkitronic® offers you a range of services that leaves nothing else to be desired, from advice, over a wide range of products to the assembly documentation system. Whether on land or in the offshore sector.

- Fast electric torque multipliers, for example for turbo-assembly applications

- Compact hydraulic torque wrench, e.g. for azimuth gears

- Efficient manual devices, e.g. for easy maintenance work

- Devices for the torque-rotation angle process, which are ideal for the assembly of rotor blades, for example

Advantages in all areas

WORK AS FAST AS THE WIND WITH US

In production, assembly or maintenance: In order to achieve the perfect result when bolting wind turbines, you should always use the most suitable bolting method. Thanks to the universal alkitronic® product range, you do not need to make any compromises, be it in terms of speed, precision or efficiency or productivity. In addition to our system consulting service we have electrical, battery-powered, hydraulic wrenches or manual torque multipliers in our program – so you are ideally prepared for any task and not bound to a specific technology!

The unique alkitronic® quality – Made in Germany – guarantees you additional performance.

|

|

|

|

|

|

Our complete product range for wind energy

|

|

|

|

|

|

|

WE TAKE YOUR APPLICATION TO THE NEXT LEVEL You have your application – we have the consulting knowledge. Together with you, we will find the right solution for your needs. With the alkitronic® bolting systems we work together on a high technical level: For the bolted connections and the wind turbine, all the way to calibration and documentation. We are very familiar with your type of system and its applica- tions. Depending on the requirements, we will put the right tool package together for you. Our high level of service always results in a long-term system partnership. Give us a try, send us your enquiry.

|

||||

|

Electrical torque multipliers with all-weather qualities

Electrical alkitronic® shut-off torque multipliers, ideal for extreme operating conditions in wind energy.

In the case of a large number of bolting processes, high speeds require a rapid working pace with high precision. Particularly in turbo-assembly applications, the devices show what they are made of. Unlike hydraulic wrenches, this eliminates the ratcheting “backward movement”, which re- sults in enormous savings in work time. Other advantages of continuous turning are higher precision due to the pre- cise achievement of torque, more reliable technology and low running costs. This is why the alkitronic® torque mul- tipliers keep performing reliably, even in spite of wind, weather and other environmental influences. Almost all models are available with protection class IP54 (protection against moisture and dust) and can therefore also be used in the rain and in the offshore area. From 100 Nm to 42,500 Nm, there is no faster and more precise bolting technology.

|

|

Your advantages:

- Intelligent motor control guarantees precise achievement of the torque and high assembly speed

- Repeat disengaging torque accuracy ± 2%

- Higher service life due to low-wear and brushless motor

- The IP54 models are protected against dust and rain

- The devices can be used in all international power grids (100 to 253 V / 45 to 66 Hz) with constant torque accuracy

- Modular software solutions for custom applications (e.g. torque/angle bollting method)

- Bluetooth interface for communication and documentation of bolting processes (with alkitronic® App)

Almost all torque multipliers are also available in an angular version. The low height is specially designed for confined spaces. The alkitronic® EA is a battery-powered torque multiplier with high mobility, always ready to use and independent of external drive energy. The alkitronic® EF torque multiplier is also available with integrated LC display and torque/rotation angle method. The alkitronic® E is a robust, indestructible 2-speed torque multiplier.

Almost all torque multipliers are also available in an angular version. The low height is specially designed for confined spaces. The alkitronic® EA is a battery-powered torque multiplier with high mobility, always ready to use and independent of external drive energy. The alkitronic® EF torque multiplier is also available with integrated LC display and torque/rotation angle method. The alkitronic® E is a robust, indestructible 2-speed torque multiplier.

Torque/angle bolting method: Highly precise and indispensable

This method is used in applications that need a higher bolting quality and require minimal friction: For example, when assembling or servicing rotor blade connections on the hub. Investigations showed that over 80% of the tightening torque is necessary to overcome the friction under the head and in the thread. In the torque/angle bolting method the friction coefficient in the thread and the bolt support no longer has an influence on the assembly preload force to be achieved.

If you want to exclude disturbances, you can rest assured with the models EFCip/ECWip. As a quality supplier, alkitronic® is always the right partner for other bolting methods.

Hydraulic torque wrenches

If the application determines the bolting method

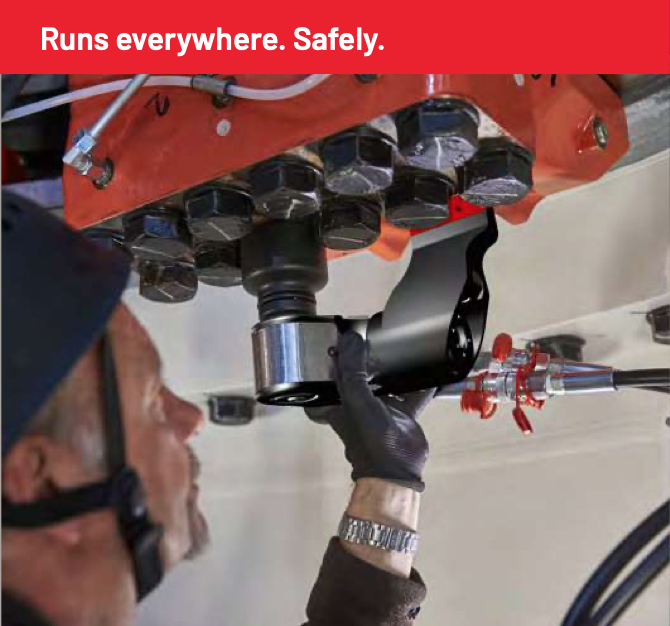

In special industrial applications or due to technical requirements, hydraulic wrenches are often the only possible alternative to handle bolted connections. For example, in very cramped, hard to access bolting processes. Here, large tightening torques can be applied even in a small space.

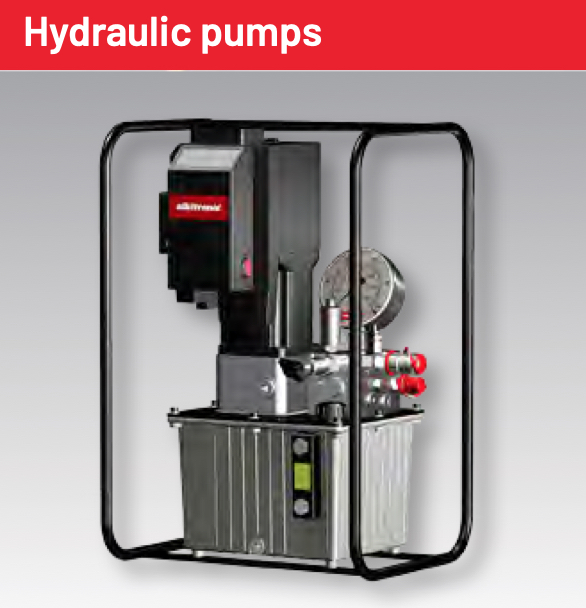

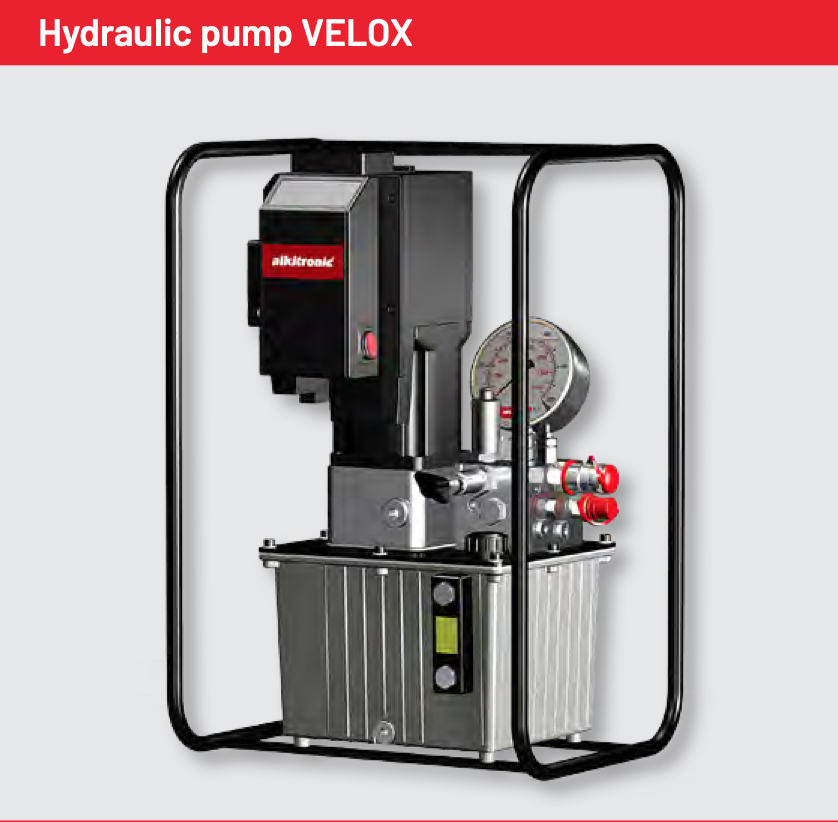

As a rule of thumb, the following is applicable to alkitronic® hydraulic torque wrenches: A torque of about 1,000 Nm can be applied to the bolted connection per kg of torque wrench weight (operating pressure 700 bar). However, a hydraulic torque wrench works relatively slowly, but very precisely with ± 3 % accuracy. For a faster, reliable operation, we recommend our alkitronic® VELOX and NOVA hydraulic pumps.

|

|

|

alkitronic® AX and AT Hydraulic torque wrench. Due to the high hydraulic pressure, the large torque and the resulting reaction forces, SAFETY is very important for our hydraulic torque wrenches. High-strength materials, backstops, handles, etc. ensure that the user has a safe tool at his disposal.

|

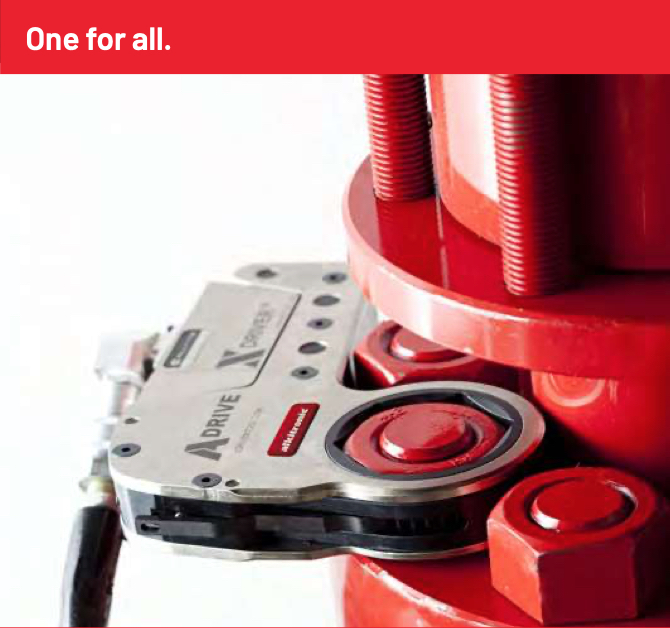

alkitronic® Norwolf X DRIVER SYSTEM. The most revolutionary hydraulic torque wrench concept. No more individual solu- tions for different applications.

|

|

alkitronic® Hydraulic torque wrench AX and AT Very suitable if heavy bolted connections with large threads must be tightened in tight spaces with high forces. Even though they can not turn so quickly due to the“ratcheting”. Hydraulic wrenches are ideal for use in explosive areas. Fast alkitronic® hydraulic pumps additionally speed up the bolting processes and save time and money. |

alkitronic® AX Combination Torque Wrench, drive unit with dual-hose system and exchangeable hexagonal head. Torques of 60-49,000 Nm, hexagonal outputs SW 14-145 mm (type- dependent).

|

|

alkitronic® AT Hydraulic Torque Wrench with dual-hose system.Torques depending on type from 110 to 72,000 Nm, thread sizes as of M 14, square output from 3/4“ to 2 1/2“ (depending on type).

|

|

|

alkitronic® Norwolf X DRIVER SYSTEM The advanced design: |

A-Drive and X-Driver are suitable for more applications than any other torque wrench. Torques from 335-83,000 Nm, hex- agonal outputs SW 27-195 mm (depending on the type).

The patented design of the hexagonal drive ensures the longest reach, allowing for an extremely large angle of attack. This way the hexagon head easily fits on the nut – without rattling or manual adjustment of the ratchet. This design makes the X Driver System the fastest heavy-duty hydraulic torque wrench.

|

|

V-Drive and X-Driver combination

Hydraulic torque wrenches for torques from 265 to 65,300 Nm, square outputs from 3/4” to 2 1/2″ (depending on type).

|

|

Hydraulic pumps, manual and cordless torque wrenches, MDS bolting technology

alkitronic® NOVA: High Speed in permanent operation, useable worldwide 100-253 V / 45-66 Hz.

The electric hydraulic pump alkitronic® NOVA is one of the fastest units on the market. Here, “idle working time” is deci- sively reduced during ratcheting.

Ideal in the wind energy sector:

Cost saving due to short assembly times.

|

|

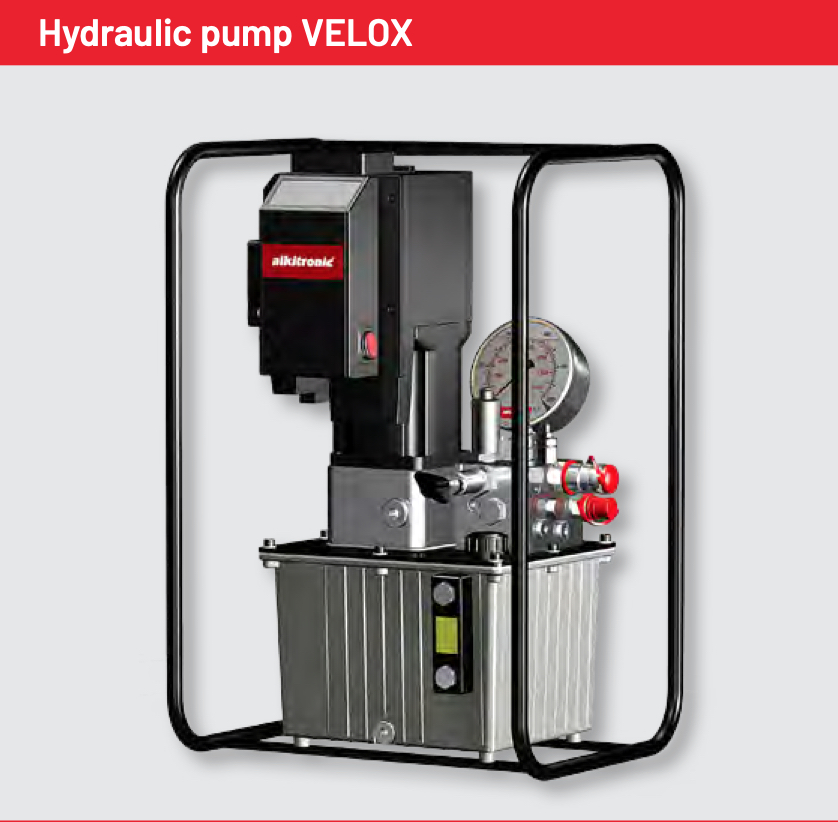

| alkitronic® VELOX Pump: Innovative quality product with optional Speed Upgrade.

|

|

|

alkitronic® Norwolf Missing LinkTM

|

alkitronic® M manual torque multipliers are THE indispens- able service tool in wind energy. There should be at least one alkitronic® M in each service vehicle. alkitronic® M are not comparable in quality with conventional manual devices. They are an extremely helpful tool, especially in mainte- nance. They offer the fullest bolting quality without annoy- ing equipment and external energy.

|

|

|

alkitronic® EA, battery-powered torque multiplier from 90 Nm to 4,000 Nm: Mobile and always ready to use.

|

|

Mounting-Documentation-Systems. MDS Bolting technology 4.0 alkitronic® HSD (manual) / EASD (battery-powered):

|

YOUR BENEFIT FOR MORE PERFORMANCE

|

Higher quality |

Higher precision |

|

Higher productivity |

Better service |