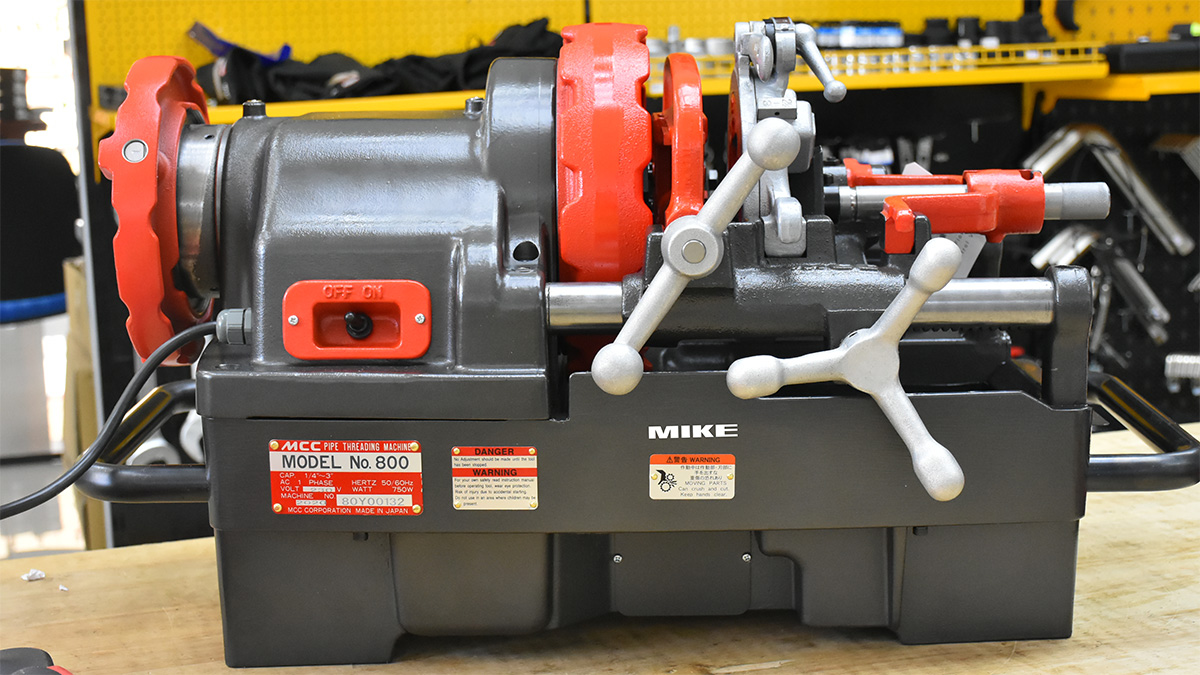

Pipe and bolt threading machine MCC 800 upto 3 inch.

Available on backorder

offers precise threading operations with automatic oiling, adjustable lubrication volume, and secure front chuck with replaceable jaws. It features a durable design, handles pipes up to 3 inches, bolts up to 1.1/4″,

€ 2,700.0

Available on backorder

Description

MCC 800 pipe and bolt threading machine, manufactured in Japan, stands as a pinnacle of precision and reliability in threading operations. Crafted with meticulous attention to detail, this machine boasts a comprehensive set of features tailored to meet the demands of professional threading tasks.

The MCC-800 arrives as a complete set, accompanied by standard accessories, ensuring seamless operation right out of the box. One notable feature is the automatic oiling system, which delivers oil directly to the dies and pipes during threading, facilitated by the die hard mechanism. This system not only enhances efficiency but also prolongs the lifespan of the equipment. Moreover, the oiling volume is easily adjustable through a simple pin-turning mechanism, providing users with precise control over lubrication.

Equipped with a front chuck featuring replaceable rocker-type jaws, the MCC-800 ensures secure gripping and precise alignment during threading operations. Additionally, the automatic switch-off carbon brush serves as a safeguard against motor overheating, further bolstering the machine’s durability and safety.

Threading machine MCC 800

Built with uncompromising quality, the MCC-800 is a product of Japanese engineering excellence. Its specifications reflect its capability to handle a wide range of threading tasks with ease. With a size capacity of up to 3 inches, it accommodates pipes ranging from 1/4″ to 3″ BSPT or NPT (C15-C75, PF1.1/2-3″) and bolts from W3/8 to 1.1/4″ or M8 to M30. Powered by a single-phase 750W 50/60Hz series motor, adaptable to various voltage requirements, and boasting a rotation speed of 23 rpm (60Hz) without load, the MCC-800 delivers consistent performance under diverse working conditions.

[youtube id=”V9byGi8fVr0″]

Complete set with standard accessories MCC-800

- Automatic oiling directly to the dies and pipe through die hard during threading operation.

- Oiling volume easily adjustable by turning pin

- Front chuck with replaceable rocker type jaws

- Automatic switch-off carbon brush to prevent motor burning

- 100% Made in Japan

Specification

- Size: 3″ Machine

- Capacity

Pipe: 1/4″-3″ BSPT or NPT C15-C75, PF1.1/2-3″

Bolt: W3/8-1.1/4″, M8-M30 - Motor: Single phase 750W 50/60Hz series motor. Adaptable to local voltage

- Rotation Speed: 23 rpm (60Hz) without load

- Weight: 63kg

- Dimension: 784(L) x 452(W) x 428(H) mm

Weighing 63kg and compactly designed with dimensions of 784(L) x 452(W) x 428(H) mm, the MCC-800 is portable yet sturdy. It comes complete with essential components such as pipe die heads, pipe dies, cutting oil, spindle bearing oil, hex keys, screwdriver, carbon brush, machine cover, tool box, and legs, ensuring comprehensive functionality and convenience.

Consist of

- Pipe Die Head(Manual): 1/4″-2″ BSPT or NPT 1 set

- 2.1/2″-3″ BSPT or NPT 1 set

- Pipe Dies: 1/2″-3/4″ BSPT or NPT 1 set

- 1″-2″ BSPT or NPT 1 set

- 2.1/2-3″ BSPT or NPT1 set

- Cutting Oil 4 liter can 1pc.

- Spindle Bearing Oil: 60 cc tube 1pc.

- Hex Key: 3,4,5,6,8mmeach 1pc.

- Crosspoint Screwdriver 1pc.

- Carbon Brush 1 set

- Machine Cover 1pc.

- Tool Box 1pc.

- Legs 1 set

Backed by a 12-month warranty and distributed by Minh Khang Equipments, the MCC-800 promises reliable operation and fast delivery, making it the preferred choice for professionals seeking top-tier threading solutions. Whether tackling small-scale projects or large-scale industrial applications, the MCC-800 stands ready to deliver exceptional results with unparalleled efficiency and precision.