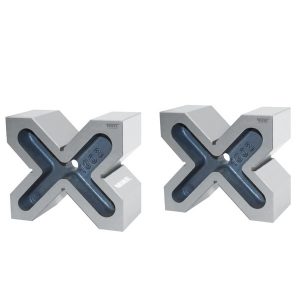

Adjustable Angle Prism, cut 90°, angle scaling 0° – 60°, 0° – 30°

made of hardened, finely ground special steel, features a 90° prism cut with 0°–60°/0°–30° angle scaling. It offers precise angle adjustments, a parallelism tolerance of ±0.05mm, and accommodates various shaft diameters.

Available on backorder

€ 113.0-€ 122.0

Description

Adjustable Angle Prism is a highly versatile tool crafted from special steel, hardened and finely ground for durability and precision. It stands out with its unique feature of an adjustable prism cut at 90°, accompanied by angle scaling ranging from 0° to 60° and 0° to 30°. This adaptability in angle adjustment is crucial, as it allows for precise positioning and measurement of workpieces at various angles, significantly enhancing the functionality of the tool in diverse applications.

Available in three sizes: 75 x 25 x 32/23 mm, 102 x 30 x 48/29 mm, and 102 x 46 x 48/29 mm, the Adjustable Angle Prism caters to a wide range of dimensions. It accommodates shaft diameters of 28 mm and 40 mm, making it suitable for various sizes of components.

- Hardened steel construction with precision-ground surfaces

- Adjustable angle range from 0° to 60°, with clearly engraved scale

- V-groove design for stable positioning of cylindrical workpieces

- High parallelism accuracy: ±0.05 mm

- Available in multiple sizes for shaft diameters from Ø28 to Ø40 mm

- Compact and rigid body suitable for bench-top and inspection setups

- Ideal for use with optical projectors, microscopes, or height gauges

- Enhances efficiency in angle-dependent measuring, marking, or machining

One of the key advantages of this tool is its parallelism tolerance of ±0.05 mm. This tolerance level ensures high accuracy in positioning and aligning workpieces, crucial in precision engineering tasks.

The utility of the adjustable angle feature in this V-Block cannot be overstated. It provides significant flexibility, allowing users to easily adjust the prism to the required angle for specific tasks. This adaptability makes the Adjustable Angle Prism an indispensable tool in settings where precision and versatility are paramount, such as in machining, calibration, and inspection processes.

Typical applications of the adjustable angle V-block

- Taper inspection on shafts: Ideal for checking the angle and straightness of Morse tapers, ISO tapers, or conical shaft ends by aligning them precisely under a profile projector or measuring microscope.

- Concentricity check at inclined positions: Supports accurate mounting of shafts at custom angles to verify concentricity or axial runout using dial indicators—especially useful when ends are not square.

- Wear pattern analysis on guide pins or ejector pins: Allows positioning of cylindrical pins at a defined tilt to observe wear zones under magnification, facilitating precision measurement or comparison.

- Angled drilling and marking operations: Serves as a stable fixture to hold round components at a fixed angle for inclined drilling, engraving, or marking tasks without complex jigs.

- Support for non-horizontal measurements: Enables users to simulate in-service angular orientations when inspecting components that operate in tilted positions, such as in molds or machinery.

Adjustable Angle Prism is a highly versatile tool crafted from special steel, hardened and finely ground for durability and precision. It stands out with its unique feature of an adjustable prism cut at 90°, accompanied by angle scaling ranging from 0° to 60° and 0° to 30°. This adaptability in angle adjustment is crucial, as it allows for precise positioning and measurement of workpieces at various angles, significantly enhancing the functionality of the tool in diverse applications.

Available in three sizes: 75 x 25 x 32/23 mm, 102 x 30 x 48/29 mm, and 102 x 46 x 48/29 mm, the Adjustable Angle Prism caters to a wide range of dimensions. It accommodates shaft diameters of 28 mm and 40 mm, making it suitable for various sizes of components.

- Hardened steel construction with precision-ground surfaces

- Adjustable angle range from 0° to 60°, with clearly engraved scale

- V-groove design for stable positioning of cylindrical workpieces

- High parallelism accuracy: ±0.05 mm

- Available in multiple sizes for shaft diameters from Ø28 to Ø40 mm

- Compact and rigid body suitable for bench-top and inspection setups

- Ideal for use with optical projectors, microscopes, or height gauges

- Enhances efficiency in angle-dependent measuring, marking, or machining

One of the key advantages of this tool is its parallelism tolerance of ±0.05 mm. This tolerance level ensures high accuracy in positioning and aligning workpieces, crucial in precision engineering tasks.

The utility of the adjustable angle feature in this V-Block cannot be overstated. It provides significant flexibility, allowing users to easily adjust the prism to the required angle for specific tasks. This adaptability makes the Adjustable Angle Prism an indispensable tool in settings where precision and versatility are paramount, such as in machining, calibration, and inspection processes.

Typical applications of the adjustable angle V-block

- Taper inspection on shafts: Ideal for checking the angle and straightness of Morse tapers, ISO tapers, or conical shaft ends by aligning them precisely under a profile projector or measuring microscope.

- Concentricity check at inclined positions: Supports accurate mounting of shafts at custom angles to verify concentricity or axial runout using dial indicators—especially useful when ends are not square.

- Wear pattern analysis on guide pins or ejector pins: Allows positioning of cylindrical pins at a defined tilt to observe wear zones under magnification, facilitating precision measurement or comparison.

- Angled drilling and marking operations: Serves as a stable fixture to hold round components at a fixed angle for inclined drilling, engraving, or marking tasks without complex jigs.

- Support for non-horizontal measurements: Enables users to simulate in-service angular orientations when inspecting components that operate in tilted positions, such as in molds or machinery.