Electric die grinder Euroboor EDG.600

Available on backorder

EDG.600 electric die grinder is easy to hold and carry and ideal for finishing dies, press working, die casting and moulding work, with a powerful 600 W (5.5 A) motor and variable speed dial with indicator.

Available on backorder

Thanks to its small and compact design, our lightweight EDG.600 electric die grinder is extremely suitable for use in tight spaces. The electric die grinder is easy to hold and carry and ideal for finishing dies, press working, die casting and moulding work. Our electric die grinder has a powerful 600 W (5.5 A) motor and variable speed dial with indicator.

|

|

|

|

|

Electric die grinder Euroboor EDG.600

- Lightweight, small and compact design for use in tight spaces

- Easy to hold and carry

- Ideal for finishing dies, press working, die casting and moulding work

- Variable speed dial with indicator

- Also available in combination with rotary burrs set

Technical data:

- Weight: 1,8 kg

- Motor power: 600 W

- Speed (no load): 12.000 – 27.000 min-1

- Collet: 6 mm

- Voltage: 220 – 240 V / 50 – 60 Hz

Manual Euroboor EDG.600

Congratulations on purchasing this electric die grinder. At EUROBOOR we strive to exceed our customers’ expectations by developing and providing premium and innovative portable drilling and cutting solutions. We believe that a professional like you must be able to rely on a professional supplier. Which has led us to become a major player in the industrial world, with our own factory and several offices worldwide. All because we have always listened to our customers and to the demands from the market.

Our vision is focused on developing innovative portable tools that add value for our customers and facilitate them in their daily work. We never lose sight of sustainability, time savings and cost savings.

Enjoy your new machine!

Before operating your new electric die grinder, please first read all instructions. You find the instructions in this manual and on the warning label on your machine. With proper use, care and maintenance your machine will provide you with years of premium grinding performance.

TO REDUCE THE RISK OF INJURY USER MUST READ AND UNDERSTAND ALL INSTRUCTIONS

To view all our offices and their contact information please visit: www.euroboor.com

The original manual has been produced in the English language. If any discrepancies should occur in translations, reference must be made to the original version for clarification.

1. Safety

1.1 General safety instructions

Do not use this electric die grinder before you have thoroughly read and completely understood this manual, specifically the “General safety instructions” and ‘’Specific safety information”, including the figures, specifications, safety regulations and the signs indicating DANGER, WARNING and CAUTION.

WARNING: When using electric die grinder, basic safety precautions should always be followed to reduce the risk of fire, electric shock and personal injury.

Please also observe the relevant national industrial safety regulations. Non-observance of the safety instructions can lead to an electric shock, burns and/or severe injuries.

This manual should be kept for later use and enclosed with the electric die grinder, should it be passed on or sold.

Work area

1. Keep your work area clean and well lit. Cluttered and dark work areas increase the chance of accidents;

2. Do not operate electric die grinder in explosive atmospheres, such as in the presence of flammable liquids, gases or dust, the power tools may create sparks which could ignite the dust or fumes;

3. Keep bystanders, children and visitors away while operating an electric die grinder. Distractions can cause you to lose control.

Electrical safety

1. The electric die grinder plugs must match the outlet. Never modify the plug in any way. Do not us any adapter plugs. Unmodified plugs and matching outlets will reduce risk of electric shock.

2. Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded;

3. Don’t expose electric die grinder to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

4. Do not abuse the cord. Never use the cord to carry the electric die grinder or pull the plug from an outlet. Keep the cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock;

5. When operating an electric die grinder, use an extension cord suitable for outdoor use, this reduces the risk of electric shock.

6. If operating an electric die grinder in a damp location is unavoidable, use a residual current device (RCD), this reduces the risk of electric shock.

Personal safety

1. Stay alert, watch what you are doing and use common sense when using an electric die grinder. Do not use it while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating the power tool may result in serious personal injury.

2. Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

3. Avoid accidental starting. Be sure the switch is off before plugging the electric die grinder in. Carrying the power tool with your finger on the switch or plugging in the power tool that has the switch on increases the chance of accidents.

4. Never place hands, fingers, gloves or clothing near rotating tool parts.

5. Remove adjusting keys or wrench before turning the electric die grinder on. A wrench or a key that is left attached to a rotating part of the power tool may result in personal injury.

6. Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

7. Use safety equipment. Always wear eye protection. Dust mask, non- skid safety shoes, hard hat and hearing protection must be used for optimal safety.

8. If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

WARNING: Wear ear and eye protection when using this power tool.

Power tool use and care

1. Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it is designed.

2. Do not use the power tool when the switch does not turn it on or off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired;

3. Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the power tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

4. Store your power tool out of reach for children and other untrained persons. Power tools are dangerous in the hands of untrained users.

5. Maintain the power tool with care. Check for misalignment of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If you detect damage, have the power tool serviced before use. Many accidents are caused by poorly maintained tools.

6. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

7. Only use accessories that are recommended by EUROBOOR for your electric die grinder. Accessories that are suitable for one tool may become hazardous when used on another tool.

8. Use the electric die grinder, accessories and tool bits etc. in accordance with these instructions and in the manner intended for the particular type of power tools, taking into account the working conditions and the work to be performed. Use of the power tools for operations different from intended could result in a hazardous situation.

Service

1. Power tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in risk of injury.

2. When servicing a power tool, use only identical replacement parts. Follow instructions in the maintenance section of this manual. Use of unauthorised parts or failure to follow maintenance instructions may create a risk of electric shock or injury.

WARNING: Remove the plug from socket before carrying out any installation, adjustment, servicing or maintenance.

Residual risk

In spite of following the relevant safety regulations and their implementation, every power tool involves a certain residual risk which cannot be completely excluded by safety mechanisms. Power tools must therefore always be operated with caution!

1.2 Specific safety information for grinding

WARNING: This power tool is intended to function as a grinder. Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

1. Operations such as sanding, wire brushing, polishing or cutting-off are not recommended to be performed with this power tool. Operations for which the power tool was not designed may create a hazard and cause personal injury.

2. Never put fingers on the switch button while moving the tool to avoid unintentional starting of the electric die grinder.

3. Ensure the mounting screws and other assemblies are fixed properly and securely before operate the electric die grinder. Turn on the switch and let the tool work for 30 seconds in a safe position. Stop immediately if considerable vibration or other defects are detected, have it repaired.

4. Do not use accessories which are not specifically designed and recommended by the tool manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe operation.

5. Always use an approved and proper guard when using the accessories.

6. The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories running faster than their rated speed can break and fly apart.

7. The outside diameter and the thickness of your accessory must be within the capacity rating of your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

8. The shank size of your accessory must properly fit the spindle of the power tool. Accessories that do not match the hardware of the power tool will run out of balance, vibrate excessively and may cause loss of control.

9. Wear personal protective equipment. Depending on application, use face shield, safety goggles or hearing protectors.

10. Hold power tool by insulated gripping surfaces only, when performing an operation where the grinding accessory may contact hidden wiring or its own cord. Grinding accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and cause electrical shock.

11. Position the cord clear of the spinning accessory. If you lose control, the cord may be cut or snagged and your hand or arm may be pulled into the spinning accessory.

12. Never lay the power tool down until the accessory has come to a complete stop. The spinning accessory may grab the surface and pull the power tool out of your control.

13. Regularly clean the power tool’s air vents. The motor fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

14. Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your clothing, pulling the accessory into your body.

15. Do not use accessories that require liquid coolants. Using water or other liquid coolants may result in electrocution or shock.

16. Do not leave the tool unattended when it is plugged into an electrical outlet. Turn off the tool, and unplug it from its electrical outlet before leaving.

1.3 Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged grinding accessory. Pinching or snagging causes rapid stalling of the grinding accessory which in turn causes the uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point of the binding.

For example, if a rotary burr is snagged or pinched by the workpiece, the edge of it that is entering into the pinch point can dig into the surface of the material causing the rotary burr to climb out or kick out .The rotary burr may either jump toward or away from the operator, depending on direction of its movement at the point of pinching.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below:

1. Maintain a firm grip on the power tool and position your body and arm to allow you to resist kickback forces.

2. Always use auxiliary handle, if provided, for maximum control over kickback or torque reaction during start-up. The operator can control torque reactions or kickback forces, if proper precautions are taken.

3. When using rotary burrs or other grinding accessories, always have the workpiece securely clamped. These grinding accessories will grab if they become slightly canted in the groove, and can kickback. When a rotary burr grabs, it may jump from the groove and you could lose control of the grinder.

4. Never place your hand near the grinding accessory. Accessory may kickback over your hand.

5. Do not position your body in the area where power tool will move if kickback occurs. Kickback will propel the tool in direction opposite to the accessory’s movement at the point of snagging.

6. Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the grinding accessory. Corners, sharp edges or bouncing have a tendency to snag the grinding accessory and cause loss of control or kickback.

7. Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent kickback and loss of control.

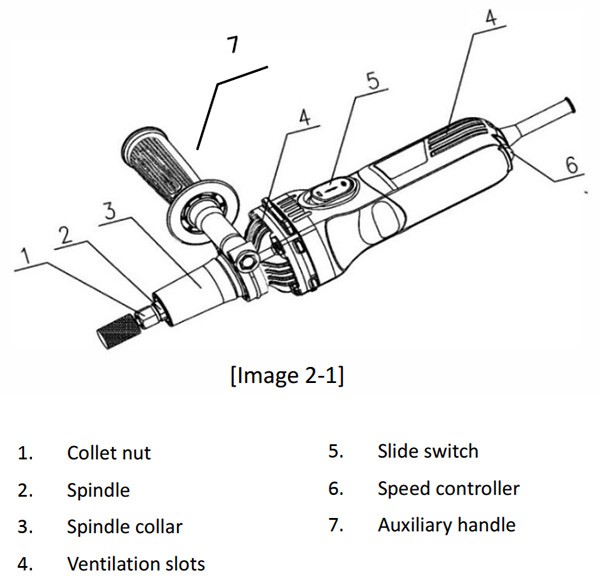

2. Description

2.1 Description and features

2.2 Box content

Note: When unpacking, make sure the parts listed below are included. If missing or broken, please contact distributors as soon as possible.

1 x EDG600 Electric Die Grinder 1 x Auxiliary handle

2 x Spare carbon brush 1 x Spindle lock spanner 1 x Collet nut spanner

1 x User manual

1 x Collet adapter 6 to 3 mm (220V/230V)

1 x 6 mm collet (220V/230V)

1 x 8 mm collet (220V/230V)

2 x 6.35 mm (1/4″) collet (120V)

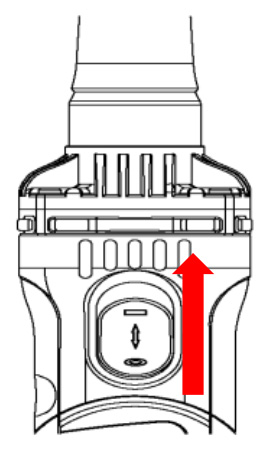

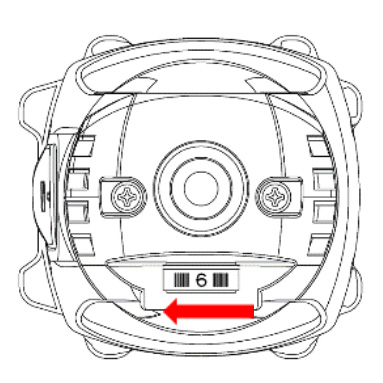

2.3 Serial number

The serial number is mentioned on the power tool two times: on the serial no. sticker on the electric die grinder shell and box. The serial number will help you, your dealer and EUROBOOR to validate and identify the power tool.

For example: 210701001

breaks down to:

| 21 | 07 | 01 | 001 |

| Year | month of manufacture | date of manufacture | Identification number |

2.4 Technical data

| EDG.600 | Metric | Imperial |

| Collets | 3 / 6 / 8 mm | 1/4″ |

| Motor power | 600 W | 5A |

| Weight | 1.8 kg | 3 lbs |

| Power cord | 2m | 78 3/4″ |

| No-load speed | 12,000 – 27,000 rpm | |

| Voltage | 220-230 V / 50-60 Hz | 120 V / 60 Hz |

2.5 Symbols

| Symbol | Term, meaning | Explanation |

| Read documentation | Be sure to read the documentation in this user manual and specifically the “General safety instructions” and ‘’Specific safety information’’. | |

| Wear ear protection | Use ear protection during operation. | |

| Wear eye protection | Use eye protection during operation. | |

| Danger/warning/caution | Read and apply the information in the adjacent text! | |

| European conformity symbol | Confirms the conformity of the machine with the directives of the European | |

| Class of protection II | Product with double layered insulation. In case of failure of the main layer of insulation the product remains safe due to a second layer of insulation. | |

| Electromagnetic Compatibility | Able to function acceptably in its electromagnetic environment. | |

| ISO9001 | Certified in accordance with ISO9001:2015 quality management system. | |

| cTÜVus | Certified by TÜV Rheinland, a recognized laboratory for safety testing approved by US federal agency OSHA and the Canadian national standards of CSA. | |

| mm | Millimetre | Unit of measure for the dimensions. |

| “ | Inch | Unit of measure for the dimensions. |

| kg | Kilogram | Unit of measure for the mass. |

| lbs | Pounds | Unit of measure for the mass. |

| V | Volt | Unit of measure for the electric voltage. |

| A | Ampere | Unit of measure for the electric current intensity. |

| W | Watt | Unit of measure for the output. |

| rpm | Revolutions per minute | Unit of measure for the revolutions. |

2.6 Environmental

![]() Separate collection. This product must not be disposed of with normal household waste.

Separate collection. This product must not be disposed of with normal household waste.

![]() Separate collection of used products and packaging allows materials to be recycled and used again. Re-use of recycled materials helps prevent environmental pollution and reduces the demand for raw materials.

Separate collection of used products and packaging allows materials to be recycled and used again. Re-use of recycled materials helps prevent environmental pollution and reduces the demand for raw materials.

Local regulations may provide for separate collection of electrical products from the household, at municipal waste sites or at the retailer when you purchase a new product.

3. Assembly

WARNING: Switch off the electric die grinder and disconnect it from the power source. Make sure the main voltages match with the machine’s rating label.

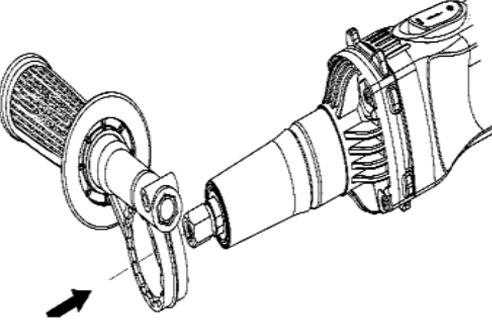

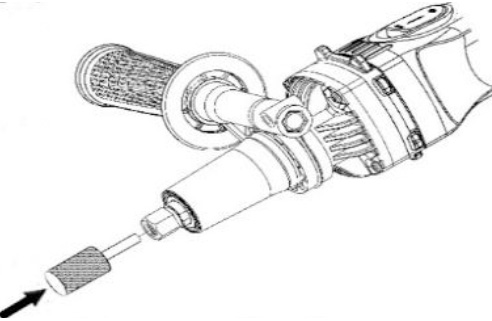

Fitting the grinding accessory

|

|

| Rotate the auxiliary handle counter clockwise to loosen the locking ring, then fix it to the fitting position of the spindle collar. | Rotate the auxiliary handle clockwise firmly. |

|

|

| Insert at least 25% of the accessory shank into the collet | While holding the spindle lock spanner in place, tighten collet nut with collet nut spanner. |

WARNING: Before each use, always check that the shank is securely fastened into the collet. After changing grinding accessory or making any adjustments, make sure the collet nut, chuck or any other adjustment devices are securely tightened.

Note: To remove the grinding accessory, proceed in reverse order. Never tighten the collet without first installing an accessory in it. Tightening an empty collet can damage the collet.

4. Using the electric die grinder

4.1 Switch action

Note: The switch on this tool is fitted with a locking device, allowing the tool to be operated for long periods of time without interruptions.

|

|

| To start the motor of the electric die grinder, push the slide switch forward (I). | To stop the motor of the electric die grinder, move the slide switch backward (0). |

4.2 Speed control

WARNING: Regardless of the speed setting, the rated speed of the grinding accessory must be at least equal to the maximum speed marked on the power tool.

|

By turning the speed controller to a given number setting from 12,000 to 27,000 rpm |

Note: If the tool is operated continuously at low speeds for a long time, the motor will get overloaded, resulting in tool malfunction.

Note: The speed adjusting dial can be turned only as far as 6 and back to 1. Do not force it past 6 or 1, or the speed adjusting function may no longer work.

4.3 General operation instruction

WARNING: Make the die grinder run idle for at least 30 seconds with the grinding accessory correctly assembled, the grinding accessory should be immediately replaced if there is the vibration. Only use the grinding accessory with shank that match the installed collet. Smaller shank will not be secure and could become loose during operation.

1. Use clamps or a vice to hold and support the workpiece to a stable platform.

2. Make sure that the power switch is in the OFF “O” position, then plug in the grinder.

3. Slide the power switch to the ON “I” position to start the motor.

4. Allow the motor to come up to full speed before touching the work surface.

5. Apply the grinding accessory to the work surface, allowing the motor to operate at full speed. If the motor bogs down, use lighter pressure.

6. To create a smoother surface, moving the grinder uniformly back and forth with light pressure.

7. Slide the switch to OFF “O” position to stop the motor.

8. Do not cover ventilation when the tool is in use. This may cause damage to the motor and reduce the efficiency of the tool.

9. Allow the motor to come to a complete stop before setting it down.

10. To prevent accidents, turn off the motor and disconnect its power supply after use.

11. Grasp grinder firmly with both hands to maintain control of the tool at start up and during use and until the grinding accessory stops.

WARNING: excessive pressure exercised on grinder may lead to high working power and overload. It increases the wear on the rotary burr or other grinding accessory and can damage the motor of the die grinder.

WARNING: Sparks generated when grinding metal. Take care that no combustible material presented on the area of flying sparks.

5. Maintenance

Your EUROBOOR electric die grinder has been designed to operate over a long period of time. Continuous satisfactory operation depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk of injury, turn the grinder off and disconnect machine from power source before installing and removing accessories, before adjusting or changing set-ups or when making repairs. Be sure the switch is in the OFF “O” position. An accidental start-up can cause injury.

Just as every power tools with moving parts, your EUROBOOR electric die grinder also needs regular maintenance service. A few recommendations follow:

1. The armature and stator (motor) is the heart of the power tool. Exercise due care to ensure they do not become damaged or affected by oil or water.

2. The carbon brushes should be checked periodically and worn-out carbon brushes should be replaced in time. After replacing, inspect whether the new carbon brushes can move freely in the brush bolder. Keep running the motor for 15 minutes to match the contact of the carbon brushes and commutator.

3. Regularly inspect all mountings and screws and ensure they are properly tightened. Should any of the screws be loose, tighten them immediately. Failure to do so may result in serious damage.

4. The supply cord of the tool and any extension cord used should be checked frequently for damage. If it is damaged, have the cord replaced by an authorised service facility. Replace the extension cord if necessary.

5. Consult the authorised service agent about the event of failure.

6. Clean the tool after each use.

6. Trouble shooting

| The motor does not work | – Damaged or defective wiring – Carbon brushes are stuck or worn out – Defective On / Off switch – Defective control unit – Defective armature and/or field |

| Motor running roughly and/or seizing up | – Bent spindle – Shaft extending from the motor is bent |

| Motor humming, big sparks and motor has no force | – Armature damaged (burned) – Field burned – Carbon brushes worn out |

| Overheating | – Blocked motor housing vents – Forcing tool to work too fast |

| Tool does not grind or brush effectively | – Accessory may be damaged, worn or wrong type for the material. |

7. Exploded View & Spare Parts List

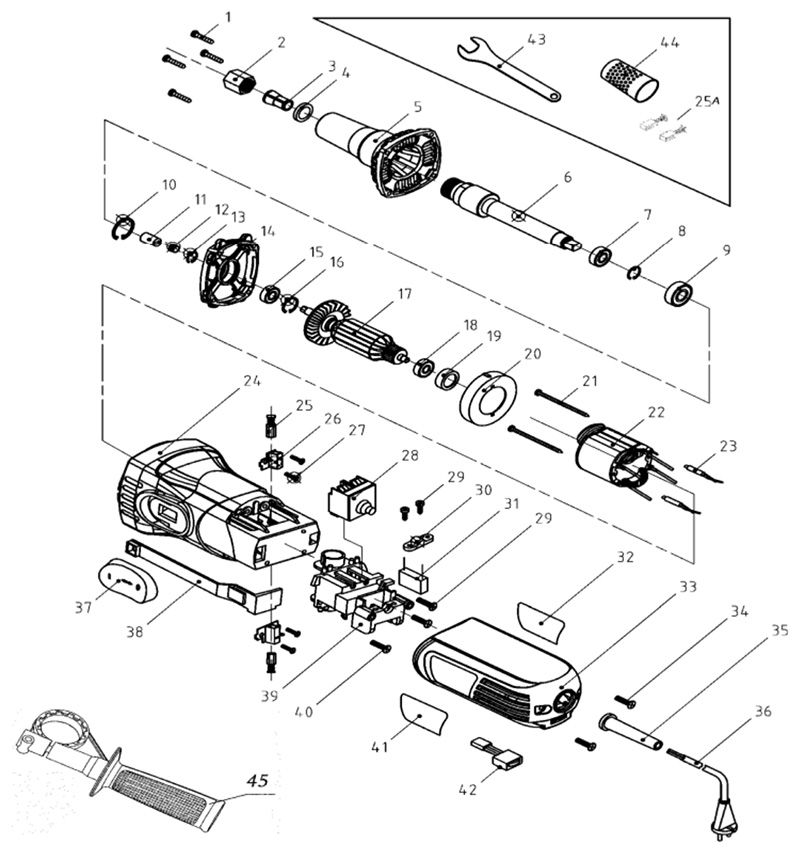

7.1 Exploded view

7.2 Spare parts list

| No | Part No. | Description | Qty |

| 1 | EDG600.0001 | Tapping screw ST4x35C | 4 |

| 2 | EDG600.0002 | Collet nut M15 | 1 |

| 3 | EDG600.0003 | Collet Ø 6 mm | 1 |

| EDG600.0046 | Collet adapter Ø 6 to Ø 3 mm | 1 | |

| EDG600.0047 | Collet Ø 8 mm | 1 | |

| EDG600.0048 | Collet Ø 6.35 mm (1/4″) | 1 | |

| 4 | EDG600.0004 | Dustproof cover | 1 |

| 5 | EDG600.0005 | Spindle collar | 1 |

| 6 | EDG600.0006 | Spindle | 1 |

| 7 | EDG600.0007 | Ball bearing 6901.2RS | 1 |

| 8 | EDG600.0008 | Circlip for shaft Ø 12 | 1 |

| 9 | EDG600.0009 | Ball bearing 6200.2RS | 1 |

| 10 | EDG600.0010 | Circlip for hole Ø 30 | 1 |

| 11 | EDG600.0011 | Adaptor | 1 |

| 12 | EDG600.0012 | Spring | 1 |

| 13 | EDG600.0013 | Circlip for shaft Ø 10 | 1 |

| 14 | EDG600.0014 | Middle cap | 1 |

| 15 | EDG600.0015 | Ball bearing 6000.2RS | 1 |

| 16 | EDG600.0016 | Circlip for hole Ø 26 | 1 |

| 17 | EDG600.0017 | Armature 220V/230V | 1 |

| EDG600.0049 | Armature 120V | 1 | |

| 18 | EDG600.0018 | Ball bearing 608.2Z | 1 |

| 19 | EDG600.0019 | Bearing bush | 1 |

| 20 | EDG600.0020 | Baffle | 1 |

| 21 | EDG600.0021 | Tapping screw ST4x60C | 2 |

| 22 | EDG600.0022 | Stator 220V/230V | 1 |

| EDG600.0050 | Stator 120V | 1 | |

| 23 | EDG600.0023 | Inductance | 2 |

| 24 | EDG600.0024 | Housing | 1 |

| 25 | EDG600.0025 | Carbon brush | 2 |

| 26 | EDG600.0026 | Brush holder | 2 |

| 27 | EDG600.0027 | Tapping screw ST4x10C | 4 |

| 28 | EDG600.0028 | Switch | 1 |

| 29 | EDG600.0029 | Tapping screw ST4x14C | 4 |

| 30 | EDG600.0030 | Cord clip | 1 |

| 31 | EDG600.0031 | Capacitor | 1 |

| 32 | EDG600.0032 | Rating label | 1 |

| 33 | EDG600.0033 | Rear cover | 1 |

| 34 | EDG600.0034 | Tapping screw 4×16 | 2 |

| 35 | EDG600.0035 | Cord sleeve | 1 |

| 36 | EDG600.0036 | Power cord 220V/230V EU plug | 1 |

| EDG600.0051 | Power cord 120V US plug | 1 | |

| EDG600.0052 | Power cord 220V/230V UK/GCC plug | 1 | |

| 37 | EDG600.0037 | Switch button | 1 |

| 38 | EDG600.0038 | Switch slide | 1 |

| 39 | EDG600.0039 | Switch holder | 1 |

| 40 | EDG600.0040 | Countersunk head screw 4×14 | 1 |

| 41 | EDG600.0041 | Brand label | 1 |

| 42 | EDG600.0042 | Speed controller | 1 |

| 43 | EDG600.0043 | Spanner | 2 |

| 44 | EDG600.0044 | Soft grip | 1 |

| 45 | EDG600.0045 | Grip handle | 1 |

7.3 Warranty and service

Euroboor B.V. warrants this electric die grinder to be free of material defects and workmanship errors under normal use for a period of 12 months after date of purchase. This 12 month period can be extended to 24 months in total by registering the product on our website: https://euroboor.com/support/register/

To maximise the lifetime of your EUROBOOR power tool always use service and parts from an official EUROBOOR distribution channel. Whenever in need of such, always contact original point of sales or if no longer existent the distributor of EUROBOOR products in your country.

7.4 CE Declaration of Conformity

EUROBOOR BV declares that the following appliance complies with the appropriate basic safety and health requirements of the EC guidelines based on its design and type, as brought into circulation by EUROBOOR BV.

| Designation/function | Electric die grinder |

| Brand | EUROBOOR |

| Types | EDG.600 |

| Ratings and principal | 220 – 230V AC, 50-60Hz, Class II |

| Characteristics | Power 600W (5A) Speed 12,000-27,000 rpm (no load) |

| Applicable guidelines | 2006/42/EC on machinery 2014/30/EU on Electromagnetic Compatibility (EMC) |

| Used standards | EN 55014-1: 2006+1+A2 | EN 55014-2: 2015 EN 61000-3-2: 2014 | EN 61000-3-3: 2013 EN 60745-1: 2009+A11 | EN 60745-2-23: 2013 |

| Testing laboratory | TÜV Rheinland |

| Zoetermeer, 2 August 2021 Albert Koster  Managing Director |

|

![]()

6.1 cTÜVus proof of certification

| Certificate No. | TU 50513022 |

| Certificate Holder: | Euroboor B.V. Kryptonstraat 110, 2718 TD Zoetermeer, Netherlands |

| Certified Product: | Handheld Angle Grinder (Electric Grinder) |

| Model Designation: | EDG.600 |

| Fulfilled Standards: | UL 60745-1:2007 R4.20 UL 60745-2-23:2013 R6.20 The standard(s) listed here reflect the status at the time of the release of this certificate |

| Date of Issue: | 2021-08-19 |

| Certificate Type: | TUV Rheinland US Mark USA standard conformity certificate The TU Certificate is based on a valid, applicable U.S. national standard in combination with all the related services such as regular factory inspections. The TUV Rheinland U.S. test mark is proof of compliance with U.S. national standards. It shows the buyer, customer, local authority having jurisdiction or consumer that a device has been successfully tested and certified by an impartial and independent testing laboratory. The principle of integrating regular spot checks into an approval, assures both the client and the buyer of continued compliance. This system guarantees the quality of the test-mark and therefore represents a credible marketing tool. |

| Certificate No. | CA 72212792 |

| Certificate Holder: | Euroboor B.V. Kryptonstraat 110, 2718 TD Zoetermeer, Netherlands |

| Certified Product: | Electric Grinder |

| Model Designation: | EDG.600 |

| Fulfilled Standards: | CAN/CSA-C22.2 NO. 60745-1-07 + GI1 + GI2 + GI3 + GI4 +GI5 CAN/CSA-C22.2 No. 60745-2-23-13 + GI1 The standard(s) listed here reflect the status at the time of the release of this certificate. |

| Date of Issue: | 2021-08-19 |

| Certificate Type: | cTUV Mark (CA-Certificate). Approval for the Canadian Market This accredited test mark, referred to as the “cTUV mark,” serves as proof of compliance with the Canadian national standards set by the Standards Council of Canada (SCC). Provincial Regulators across Canada recognize the cTUV mark as proof of product compliance to mandatory Canadian regulatory and code requirements. Retail buyers accept it on products they’re sourcing. Consumers recognize it on products they purchase as a symbol of safety. It shows that a product has been successfully tested and certified for safety by an impartial and independent testing laboratory accredited by the SCC. TÜV Rheinland tests a product sample and conducts repeat factory inspections to assure continued compliance. The validity of the certificate does not expire unless the standard(s) expire or the client cancels the certificate. Certified products may be labeled with a test mark. |