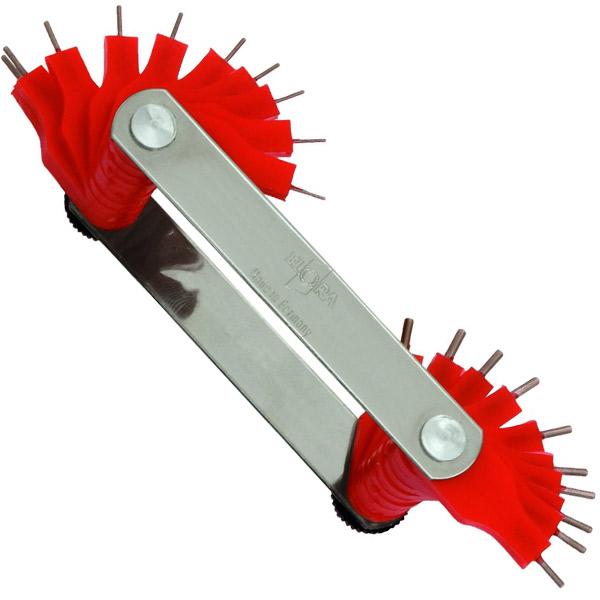

Nozzle Gauges Elora 194, Made in Germany

SKU: 194Elora 194 is a set of metal gauges to measure conduit size accurately. Nozzle gauge (diesel injector nozzle tester) measures the size of the nozzle hole in diesel fuel injectors for optimal engine performance.

Elora 194 is a set of metal gauges designed to measure the size of liquid or gas conduits. The gauge set includes precise, polished metal pins made of high-grade tool steel to ensure accuracy and high durability. The pins are designed to be interchangeable and have different diameters to fit different conduit sizes. This gauge set is used in industrial, mechanical, and construction applications to measure the length and diameter of conduits and grooves.

What is another name for “nozzle gauge” and what is it used for?

A”Nozzle gauge,” also known as “diesel injector nozzle tester,” is a measuring tool used to measure the size of the nozzle hole in diesel engine fuel injectors. The tool is designed with soft metal measuring pins to avoid damage or scratches to the injector’s surface, and the pins are numbered for easy reading of the measurement results.

Diesel engine fuel injectors have very precise hole sizes that are critical to ensure efficient engine operation. Using a “nozzle gauge” to measure the nozzle hole size ensures that the fuel injectors are operating correctly and increases engine performance.

The “nozzle gauge” is often used in engine maintenance and repair centers and is an essential tool in the production lines of fuel injector manufacturers.

How to use a nozzle gauge?

To use a “nozzle gauge” to measure the nozzle hole size in diesel engine fuel injectors, you can follow the steps below:

- Choose the appropriate measuring pin size for the injector nozzle size. The pin must have a diameter smaller than or equal to the nozzle hole diameter.

- Gently place the measuring pin into the injector nozzle hole, making sure that the pin is centered in the hole.

- Read the measurement result on the measuring pin. The result is read at the point where the pin touches the surface of the injector.

- If the measurement result is outside the allowable range or not correct for the required size, you need to change the measuring pin size and repeat the measurement process.

Note that when using a “nozzle gauge,” you must ensure that the injectors being tested are clean and dry. If the injectors are dirty or moist, the measurement result will be inaccurate. Additionally, the accuracy and precision of the measuring tool must be ensured by periodic checking and calibration.

| SKU | Add | Pieces |

|---|---|---|

| 194-16M | 16 | |

| 194-20M | 20 |

- Pending orders